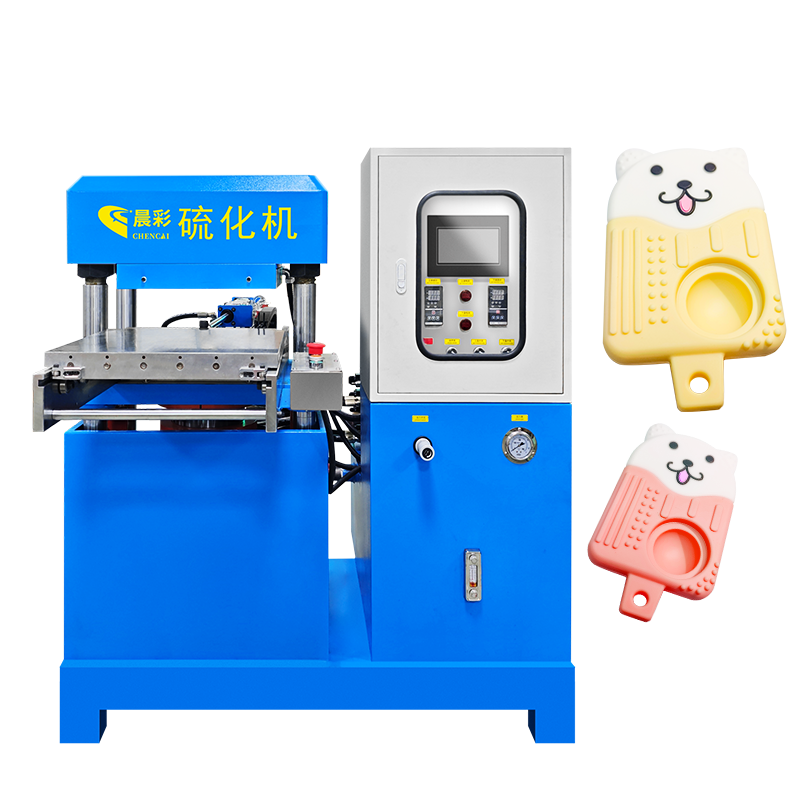

Vulcanizing Machine: A Modern Alternative for Ecological Manufacturing

In the field of production, a vulcanizing machine has become an ecological and sustainable option.

The Capabilities of Vulcanizing Machine

At the core of the vulcanizing machine is vulcanization – a chemical process that converts rubber or other related polymers into materials with improved durability. This technique increases the hardness, elasticity as well as weather resistance of rubber making it applicable for many different uses.

Being Eco-friendly in Manufacturing

Among establishments involved in manufacturing, vulcanizing machines are exceptional due to their green practices. This means that it operates using very little energy which ensures low carbon emission to the environment. In addition, water cooling systems are employed by this device thus helping to minimize heat wastage and consequently promoting sustainability in terms of ecology.

Flexibility and Productivity

Not just being environmentally friendly but also having versatility and efficiency are characteristics associated with vulcanizing machines. It can work on various substances such as natural rubber or synthetic polymers while applicable across different sectors like the automotive industry; aerospace industry among others consumer goods sector too.Its automatic operation guarantees high productivity levels because there is less need for manual labor hence faster production rates achieved consistently over time.

Safety Features and Longevity

Another thing worth mentioning about vulcanizing machine is their safety record even during tough jobs; they are built strong enough not only to withstand such conditions but also protect workers from harm.Their robustness ensures safe working conditions while at the same time guaranteeing performance reliability throughout its lifespan thus making them durable machines indeed.

Conclusion

To sum up, vulcanizing machine represents an environmentally friendly method towards manufacturing things greener which also shows adaptability, effectiveness, safety measures together with staying power so necessary within any productive venture.Thus demonstrating how innovations can be realized without harming our planet further through industrial activities.

Weather Resistant Silicone Labeling Machine: Elevating Your Production Efficiency and Durability

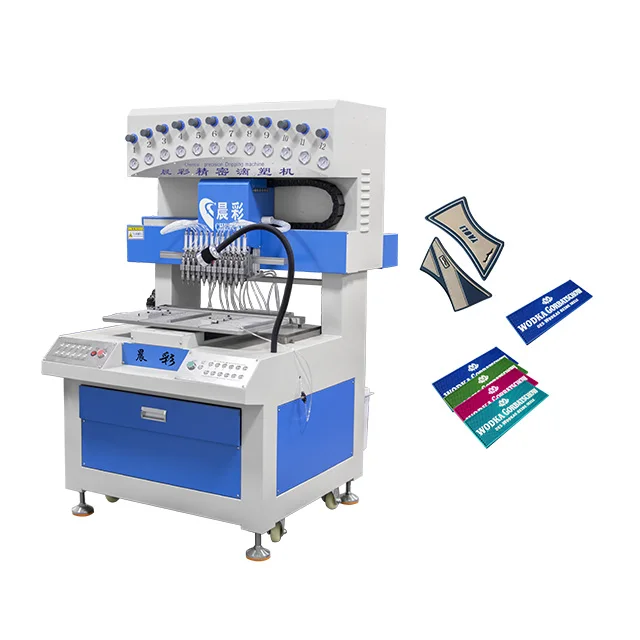

ALLPVC tag making machine: A modern labeling solution that saves energy

NextRecommended Products

Hot News

-

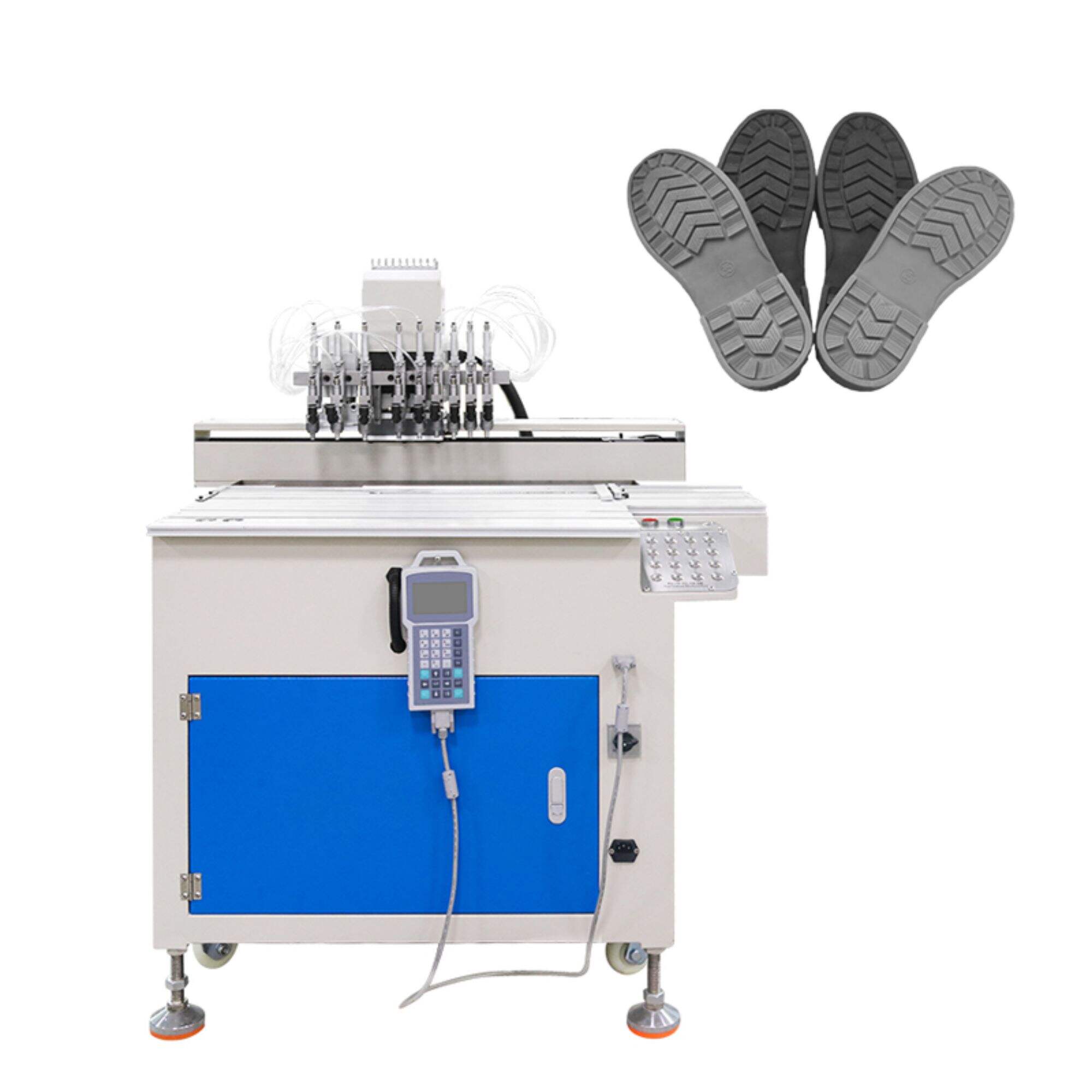

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY