PVC tag making machine: A modern labeling solution that saves energy

In the present fast-moving and environmentally-friendly world, The PVC tag making machine is an innovation that has made this possible. It is not only efficient but also eco–friendly since it can produce personalized labels or tags in bulk.

The Emergence of PVC Tag Making Machines

Polyvinyl chloride (PVC) is among the most used materials because of its versatility and durability; it can resist water, stabilize chemicals, and is cheap. This makes it suitable for many industries hence why there are so many different PVC tag making machine such as badges, signs, etc., which can be produced by machines like these.

Energy Saving is Paramount

One good thing about PVC tag making machines is that they conserve energy. In contrast with conventional methods where work may require more people or old-fashioned equipment which will utilize a lot of power supply, current models have been designed following technological advancements meant to reduce consumption rates. PVC tag making machines include accurate servomotors and hibernate functions for saving electricity during standby periods among other things.

Offers variety in terms of customization

Another feature which makes PVC tag making machine stand out from others available on the market today is their ability to be customized depending on individual preferences or business needs. There are different fonts sizes templates etc., which one could choose when making his/her own unique design using various printing technologies such as screen printi9ng etc . From simple barcodes labels up-to complex security tags all should have clean cuts through precise cutting technology incorporated within each unit thus ensuring accuracy throughout production process .

Environmental friendliness factor

There are several ways through which adoption of pvc tag making machine contributes towards environmental sustainability. To begin with, automation reduces waste generation during manufacture stage since there will be minimal off-cuts produced unlike what would happen if manual cutting was used. Recycling can also be done with these materials after use because they are made up entirely of PVC and this makes them perfect for reusing purposes too .

Improving efficiency levels while increasing productivity

PVC tag making machine ensures that a lot is accomplished within the shortest time possible thus saving much needed man hours which could have been spent doing other things. Its capability to produce numerous items simultaneously at high speeds means meeting deadlines will be very easy leading to enhanced organizational effectiveness in general.

In summary,

In conclusion, The PVC tag making machine is energy conservative hence suitable for today’s businesses. It can also be used to improve efficiency in production while minimizing waste during labeling process as well as reducing customization costs among organizations.

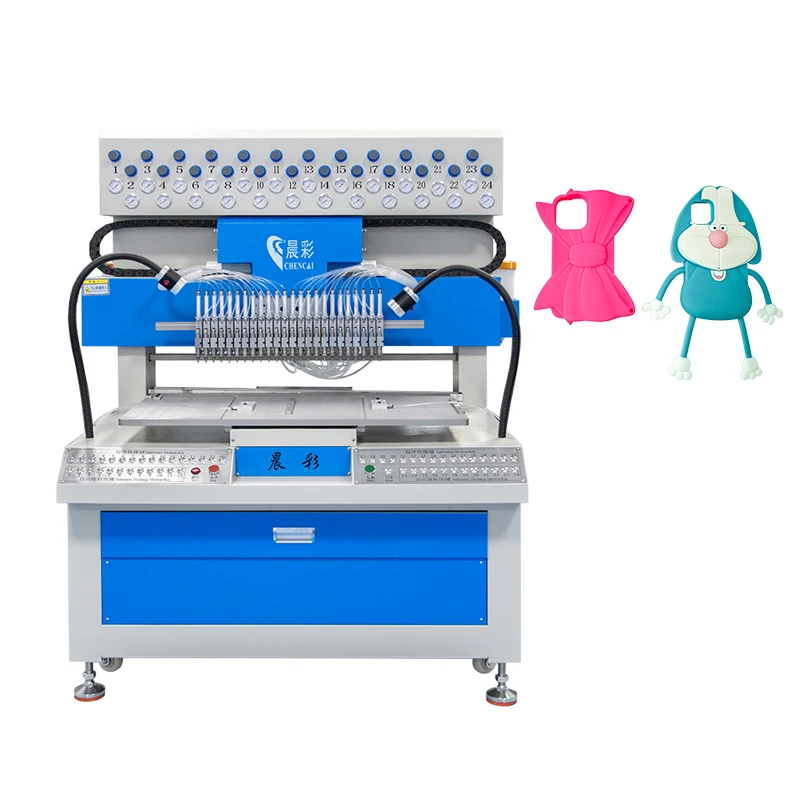

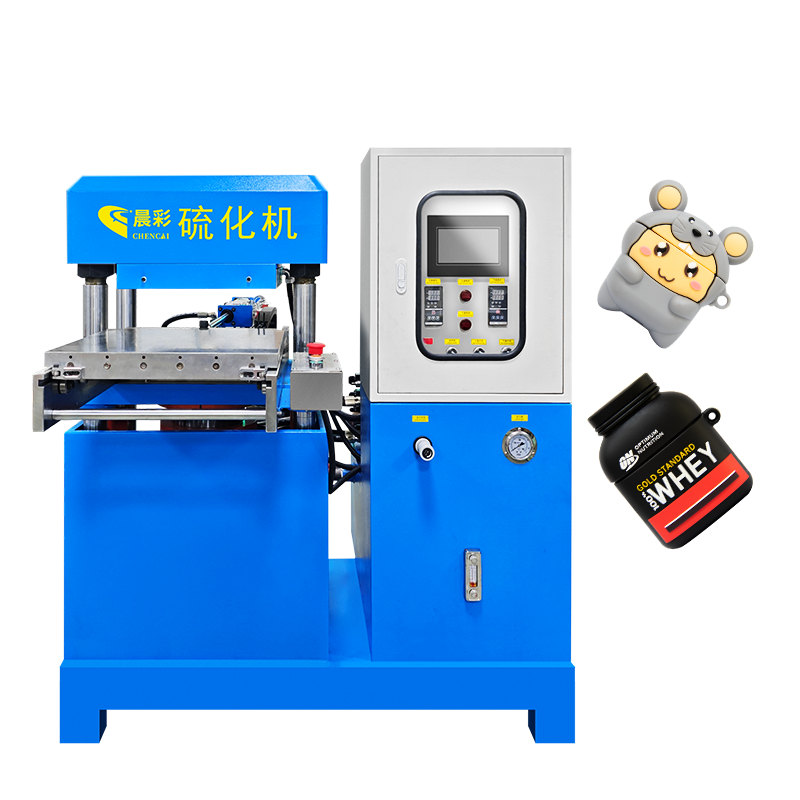

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY