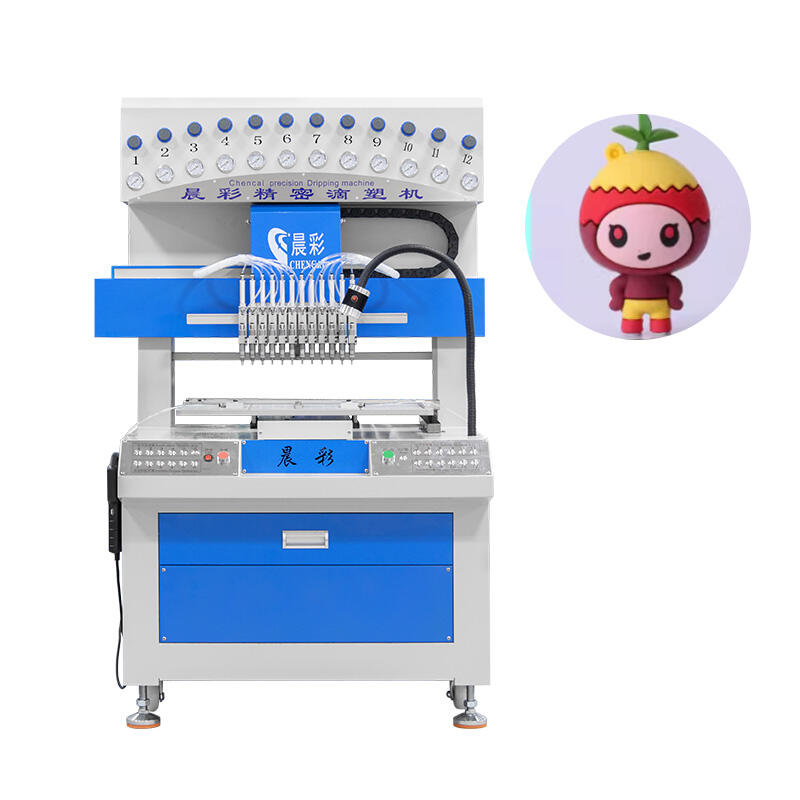

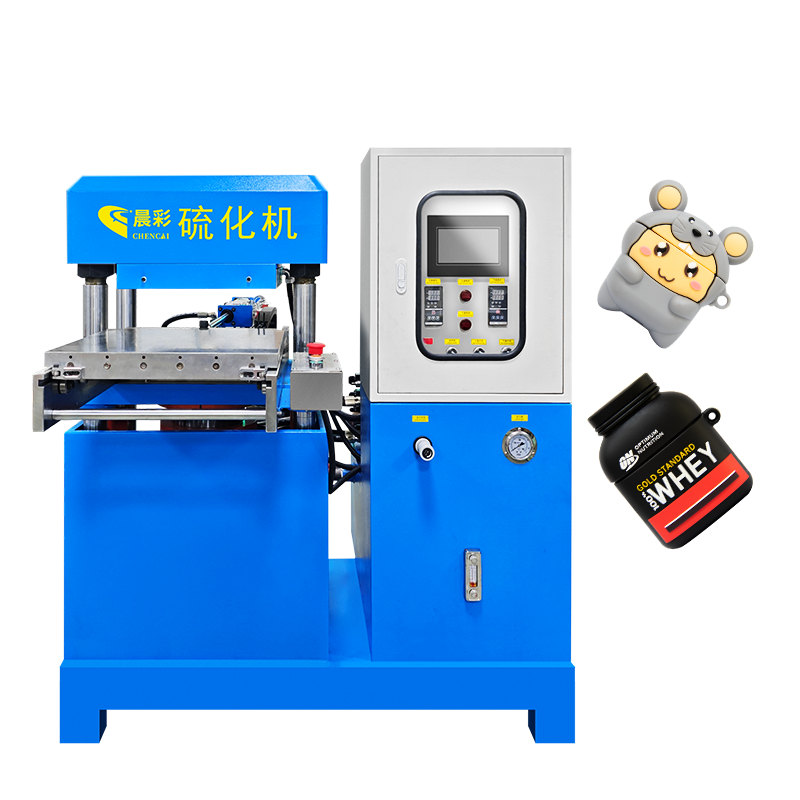

Weather Resistant Silicone Labeling Machine: Elevating Your Production Efficiency and Durability

In the context of modern manufacturing, the Weather Resistant Silicone Labeling Machine has been designed with robustness in mind so that it can be used across various sectors for labeling purposes.

Importance of Being Waterproof

Weather Resistant Silicone Labeling Machine can survive under severe environmental conditions as it is made from a material resistant to them all. What this means is that wherever there may be exposure to moisture or extreme temperatures or chemicals that erode things quickly – outdoors, for example – one should use these types of labels. The labels created are long-lived because silicone does not crack or fade easily even if faced with unfavorable weather conditions.

Increasing Output per Unit Time

The main feature distinguishing the Weather Resistant Silicone Labeling Machine from their counterparts lies within its ability to increase production rates tremendously. This happens by eliminating mistakes caused by human error through automation thereby saving time that would have been spent doing each task manually. Additionally, precision-engineered parts combined with state-of-the-art technologies used in these devices ensure accurate placement of tags thus enhancing overall product quality while reducing wastage.

Flexibility and Adaptability

Another advantage associated with using a Weather Resistant Silicone Labeling Machine is versatility; this means being able to handle different materials, shapes and sizes among other things during labelling processes. It can therefore be used for any kind of container whether small bottles or large drums used in industries such as chemical manufacturing firms amongst others. Moreover customization options available allow creation unique stickers which resonate well with your brand identity and message.

Strength and Longevity

In addition to being water resistant thanks to its construction using silicones also contribute towards durability levels exhibited by Weather Resistant Silicone Labeling Machine over time. Unlike most substances known today for their susceptibility towards wear tear effects brought about mainly due friction between moving parts such as metals – plastics etc., silicones are less affected thus making these machines last longer even with heavy usage rates. In this regard it lowers maintenance costs while keeping production lines running smoothly without frequent breakdowns.

Environmentally Friendly

Weather Resistant Silicone Labeling Machine do not require regular replacement like other types of labels do, those made from durable materials minimize landfill volumes thereby reducing ecological impacts which may arise during labeling processes within organizations. Furthermore power consumption levels are quite low hence making them more energy efficient compared to their counterparts thus promoting greener manufacturing practices.

Conclusion

In conclusion therefore there can be no doubt whatsoever that incorporating Weather Resistant Silicone Labeling Machine into your labels or packaging would greatly enhance both their life spans and overall appearance as well; so why wait? Take action today!

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY