Chencai brand silicone rubber milling milling equipment is favored by the market for its efficient processing capacity and stable operating performance, and now provides preferential wholesale programs for our customers.

With the advent of the era of intelligent manufacturing, rubber mixing machine has evolved from a single mixing tool to an integrated and automated key equipment. The intelligent rubber mixing machine developed by Chencai Automation Equipment Co., Ltd. integrates advanced technologies such as the Internet of Things and big data, making the rubber mixing process more transparent and refined, and helping enterprises to move to a new stage of intelligent production.

By monitoring and analyzing the parameters in the mixing process in real time, the intelligent rubber mixing machine automatically adjusts the best mixing conditions, significantly improving the consistency and stability of rubber products. At the same time, based on remote diagnosis and predictive maintenance functions, Chencai intelligent rubber mixing machine has greatly reduced the equipment failure rate and maintenance costs, and has brought significant economic benefits to enterprises.

In the face of the sustainable development needs of the rubber products industry, Chencai intelligent rubber mixing machine is not only committed to improving production efficiency, but also pays more attention to the implementation of environmental protection concepts.

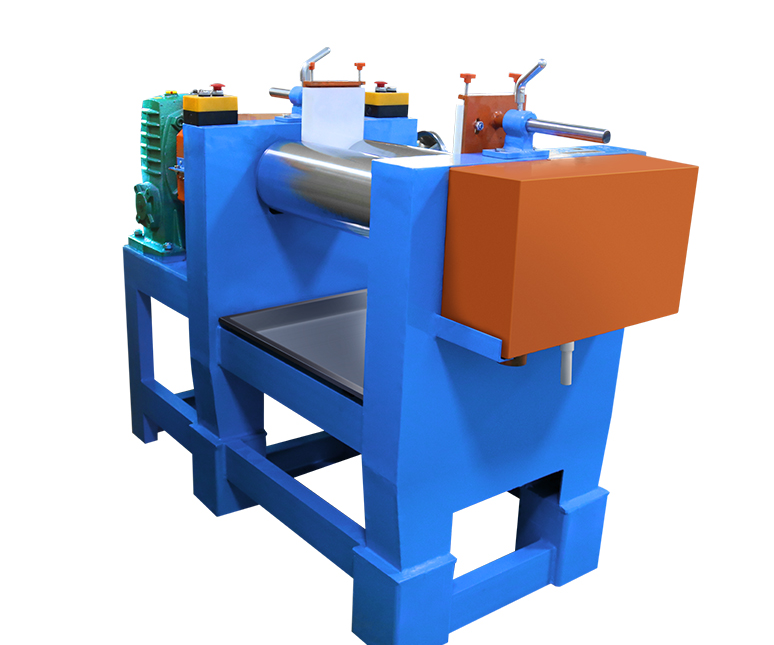

The Chencai Silicone Rubber Milling Machine is a game-changer in the processing of silicone rubber materials. This innovative machine offers a streamlined and efficient milling process, revolutionizing production workflows.

The Chencai Silicone Rubber Milling Machine boasts advanced milling technology, ensuring accurate and consistent results. Its variable speed control allows for precise adjustment, accommodating different milling requirements. This precision control not only enhances product quality but also improves production efficiency. Additionally, the machine's robust construction ensures longevity and reliability, further minimizing downtime and operational costs.

In conclusion, the Chencai Silicone Rubber Milling Machine offers a comprehensive solution for silicone rubber processing. Its advanced technology, user-friendly design, and exceptional performance make it a must-have for silicone rubber manufacturers and processors seeking to improve their production efficiency and quality.

The Chencai Silicone Rubber Milling Machine is a precision tool designed for milling silicone rubber materials. It offers a highly efficient and consistent milling process, ensuring accurate results.

The Chencai Silicone Rubber Milling Machine features advanced milling technology, providing precise control over the milling process. It offers variable speed control, allowing users to adjust the milling speed according to their specific needs. This ensures that the silicone rubber is milled to the desired fineness, resulting in uniform and consistent products.

Whether you are a manufacturer or processor of silicone rubber products, the Chencai Silicone Rubber Milling Machine is an essential tool for achieving accurate and efficient milling. Its advanced technology, user-friendly design, and exceptional performance make it a must-have for anyone serious about silicone rubber processing.

With the advent of the era of intelligent manufacturing, rubber mixing machine has evolved from a single mixing tool to an integrated and automated key equipment. The intelligent rubber mixing machine developed by Chencai Automation Equipment Co., Ltd. integrates advanced technologies such as the Internet of Things and big data, making the rubber mixing process more transparent and refined, and helping enterprises to move to a new stage of intelligent production.

By monitoring and analyzing the parameters in the mixing process in real time, the intelligent rubber mixing machine automatically adjusts the best mixing conditions, significantly improving the consistency and stability of rubber products. At the same time, based on remote diagnosis and predictive maintenance functions, Chencai intelligent rubber mixing machine has greatly reduced the equipment failure rate and maintenance costs, and has brought significant economic benefits to enterprises.

In the face of the sustainable development needs of the rubber products industry, Chencai intelligent rubber mixing machine is not only committed to improving production efficiency, but also pays more attention to the implementation of environmental protection concepts.

Dongguan Chencai Automation Equipment Co,. Ltd was established in 2017, and we have 15+ years of experience in this industry. It has been committed to the research and development and production of equipment machines for a long time. We have a high-quality and highly-educated management team. Together with the R&D team, we continue to introduce many innovative automatic dispensing machines, coloring, dispensing and baking molding equipment. We provide high quality and process efficiency for your production, warmly welcome new and old customers to visit us!

Chencai is an elite team of senior R&D personnel, we continue to introduce many innovative automatic dispensing machines, coloring, dispensing and baking molding equipment.

Dongguan Chencai Automation Equipment Co., Ltd. has more than 15 years of industry experience, has been with its rigorous and pragmatic attitude, the spirit of excellence, continuous accumulation and transformation of rich production experience, to create greater value for customers.

Chencai Automation Equipment Co., LTD., as the source manufacturer, adheres to the direct supply mode, reduces the intermediate links, and ensures that the whole process of product design, production and delivery is controllable and efficient.

Chencai provides a full range of high quality after-sales service guarantee for the supplied automation equipment.

Yes, our milling machines are designed to process various types and hardness grades of silicone rubber, from soft to hard durometers.

Our machines incorporate advanced cooling systems that maintain optimal temperatures during the milling process to prevent overheating and damage to the silicone material.

Tool changes are straightforward and quick, following standardized procedures. Our machines often feature automatic tool changers for increased efficiency.

Our milling machines are engineered with energy-saving technologies to minimize consumption without compromising performance.