Pay attention to the double improvement of quality and performance, to provide the end consumer with excellent baking experience and satisfactory product quality.

Synonyms for a good time: We’re talking about the baking table, baby! When you think about it, it’s everywhere. From plastic to rubber to electronics and even printing, this is one versatile piece of machinery.

We’ll take a look at its role in each industry. In plastics and rubber, the baking table is used to melt these materials down so they can be molded into specific shapes. It’s all about temperature and heating methods here.

In the electronics world, this bad boy plays a crucial part in manufacturing circuit boards and connectors. Same goes for electronic components. With thermal processing techniques on lockdown, this machine makes sure nothing goes wrong with those tiny computer brains we use every day. Over in printing though? It’s all about drying out those pretty pictures.

When you look at it overall, the baking table’s got a lot of responsibility on its shoulders. But what do you expect from something that enhances product quality and production efficiency? They didn’t stop there either – we’re seeing more advancement in technology so there might not be any stopping them now!

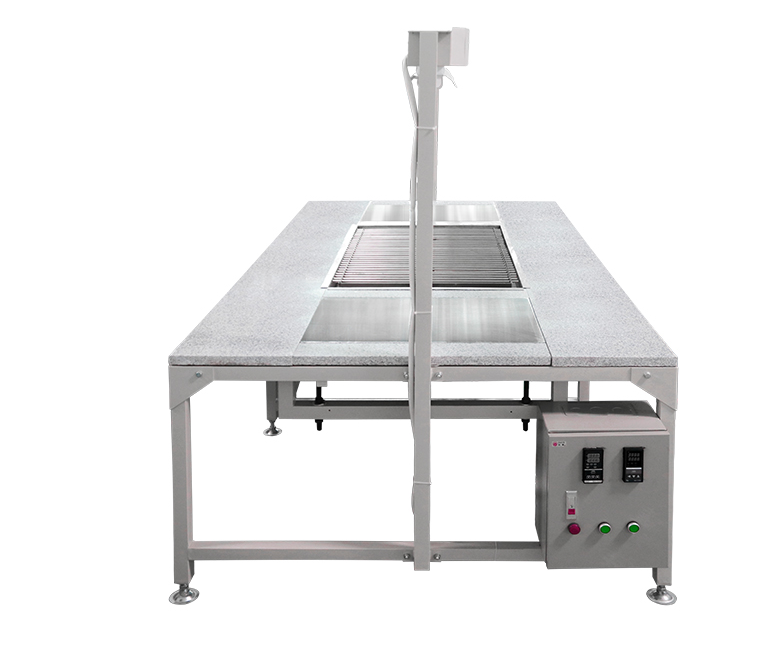

The industrial baking table is a grand piece of equipment. It's advanced temperature control technology solidifies its reputation for consistent and accurate temperatures throughout the baking process. The results you will get from this table will be unmatched and in doing so, it also reduces energy consumption.

Not only are these tables built to survive the manufacturing world, but they can bake multiple items at once with their large surface area. On top of that, cleaning them is as simple as can be. They're designed with non-stick surfaces to make maintenance a breeze. With such little downtimes, you won't have to worry about your production slowing down.

The temperature control capabilities on this thing are truly exceptional. Whether its used for food, or some other scientific purpose, trust us when we say this table hits the mark for a range of industrial applications. So why wait? Contact us today!

Chencai Industrial Automatic baking table is like a hitman, but for making good food. Bake faster, cheaper, and better with the Chencai industrial automatic baking table. The latest in automation tech allows for uninterrupted production line operation.

Keep your baked goods consistent and stable by using the machine's automatic control feature that accurately controls temperature and time. This new machinery not only improves product quality, also reduces human interaction and potential errors from that.

It’s also fast as hell and won’t cost you an arm or a leg to operate it! You can adjust its powers on demand to effectively use energy while reducing consumption and costs. Save money while saving the planet? Sounds like a win win if you ask me!

In conclusion, Chencolor Industrial Baking Table is the future of bakery production lines. Take advantage of their machine to make your business competitive and meet modern day needs for efficiency & environmental protection.

As a professional pastry table manufacturer, Chencai is leading the future of pastry mold technology. With an intelligent control system.

First, this baking table has a cutting-edge intelligent control system. This feature allows for accurate control of important things such as temperature and time. The operator can manage the entire molding process with preset procedures or real-time controls. This ensures that production is both efficient and stable.

Secondly, the data recording and analysis function of this system lets you monitor equipment operation status and production data in real time. Through analyzing data, manufacturers are able to get a better understanding about performance and efficiency. Then they can use these findings to improve on product quality.

Finally, this intelligent control technology also comes with expansion capabilities. By combining this system with IoT and cloud computing tech it opens up possibilities like fault diagnosis and data analysis functions. This improvement overall raises the intelligence level of the equipment while boosting production efficiency at the same time.

Dongguan Chencai Automation Equipment Co,. Ltd was established in 2017, and we have 15+ years of experience in this industry. It has been committed to the research and development and production of equipment machines for a long time. We have a high-quality and highly-educated management team. Together with the R&D team, we continue to introduce many innovative automatic dispensing machines, coloring, dispensing and baking molding equipment. We provide high quality and process efficiency for your production, warmly welcome new and old customers to visit us!

Chencai is an elite team of senior R&D personnel, we continue to introduce many innovative automatic dispensing machines, coloring, dispensing and baking molding equipment.

Dongguan Chencai Automation Equipment Co., Ltd. has more than 15 years of industry experience, has been with its rigorous and pragmatic attitude, the spirit of excellence, continuous accumulation and transformation of rich production experience, to create greater value for customers.

Chencai Automation Equipment Co., LTD., as the source manufacturer, adheres to the direct supply mode, reduces the intermediate links, and ensures that the whole process of product design, production and delivery is controllable and efficient.

Chencai provides a full range of high quality after-sales service guarantee for the supplied automation equipment.

Chencai baking table can be customized. According to customer requirements, we can provide different specifications, heating power and temperature control accuracy of the baking table.

Yes, hygiene and sanitation are top priorities.Our industrial baking mold tables feature seamless construction and non-porous finishes, making them simple to clean and sanitize.

Absolutely. Our baking tables are designed to tolerate high heat exposure without warping or damage, making them suitable for placement near ovens and hot equipment.

The design of our industrial baking mold tables includes insulation layers and heat-diffusing surfaces that promote uniform heat transfer across the table's surface.Additionally, we can equip them with heating elements and temperature control systems if needed.