Working Principles and Performance Optimization of Silicone Rubber Milling Machines

How Do Silicone Rubber Milling Machines Function?

The process of servicing a silicone rubber milling machine starts from the placement of unfabricated silicone rubber onto the table of the machine. Depending on its purpose or model, such material may be placed into the machine either manually or automatically. The silicone rubber milling machine employs a number of rotating tools or bits which perform cutting and shaping tasks on rubber as commanded in the program.

Milling is broad and may include but is not limited to such operations as drilling, sloping, planning, or contouring. The operations of the silicone rubber milling machine are also necessary since they determine the precision of the parts produced and consistency with the required tolerances common in production industries for automotive or aerospace or medical apparatus.

Increased Performance Via Optimization Strategies

Apart from the key performance indicators, periodic optimizations should also be performed. This includes temporal activities such as aligning the cutting tools, cleaning the machine, lubricating the moving parts, and so on. Calibration is a critical aspect and it ensures that this type of machine work inside the prescribed tolerances thus minimizing waste and enhancing the quality of the parts.

The silicone rubber milling machine’s overall performance and the resulting product’s quality can be greatly enhanced by picking the right tool for the job, as well as choosing the appropriate machining parameters. Depending upon the grades of silicone rubber used, some special tool angles and cutting conditions may deliver great results.

The majority of currently used silicone rubber milling machine are equipped with sophisticated control systems that enable them to be operated within pre-set limits and modify process parameters in real time, if necessary. These systems automatically adjust cutting parameters based on material variations to improve consistency with less operator involvement.

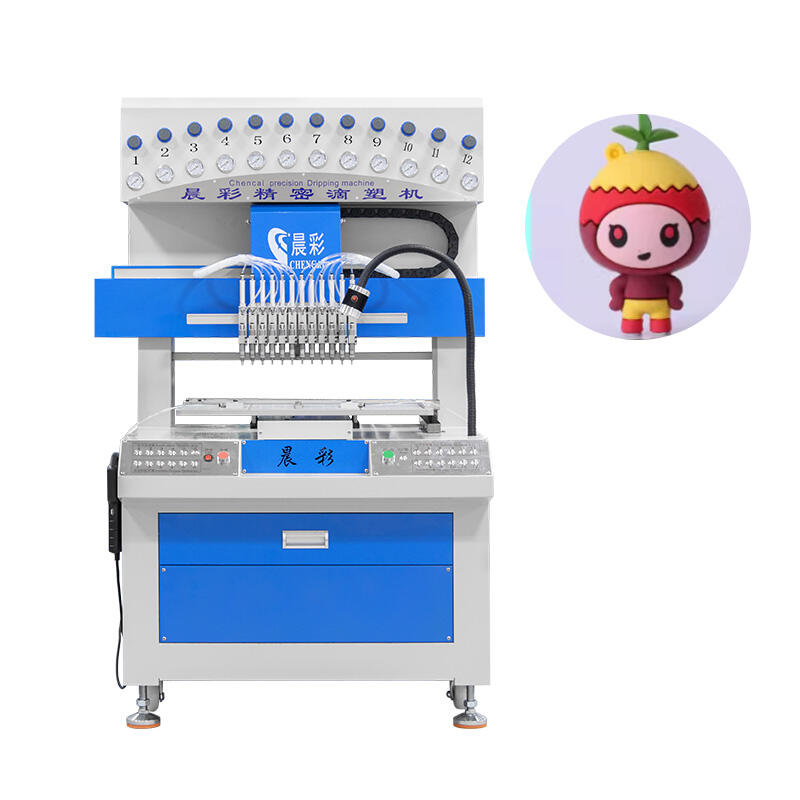

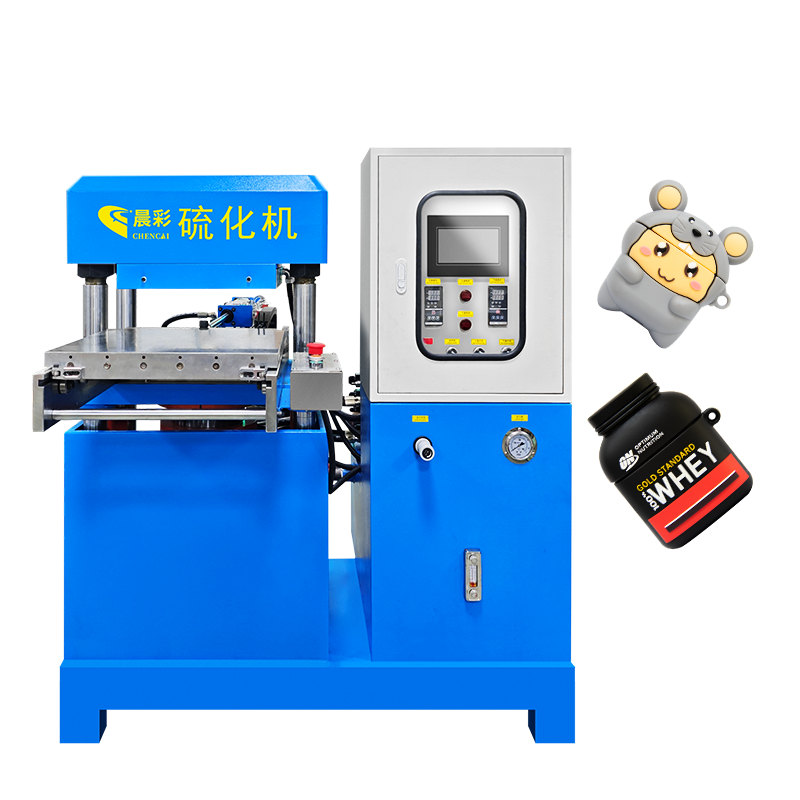

Chencai's Range of High-Quality Milling Solutions

Chencai brings you modern silicone rubber milling machines that are precise and offer great efficiency in the manufacturing of products. We place so much effort and energy in improving and innovating our machines in order to ensure great performance and reliability.

Check our products to see what unique features of our silicone rubber milling machine help in enhanced production. Chencai, on the other hand, has the capability and experience to help your business grow in the way that you want, whether it is a basic version or a bespoke machine enabled to your various business needs.

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY