A Comprehensive Guide to Baking Tables: From Design to Practical Use

Baking Tables: Basic Design Principles

The design aspect of baking tables must combine practical usage, strength, and efficiency. Other features include material types where high-quality heat resistant Steel or alloys are ideal for baking tables since they are capable of withstanding heat and corrosive environments. Structural support also has to be considered where strong frames and legs materials prevents bending or warping due to high loads or excessive heat.

From Concept to Reality: The Manufacturing Process

Baking tables are designed by engineers working with the relevant industry to ensure that all the functional requirements, as well as safety requirements would be met and are been drafted. The first prototypes are constructed and then put throughout a range of productivity tests to ensure efficiency and even spotting errors in the design.

Different industrial methods of manufacturing are used to manufacture parts of the baking table and the parts are assembled with precision. All completed units are subjected to rigorous quality control processes so that any defects are eliminated. The final stages of completion are refinishing the surfaces of the product and packing it before transportation.

Practical Applications of Baking Tables

Baking tables, although frequently used in pastry kitchens, have other industrial uses, particularly in molding PVC products and in using glue with the following processes:

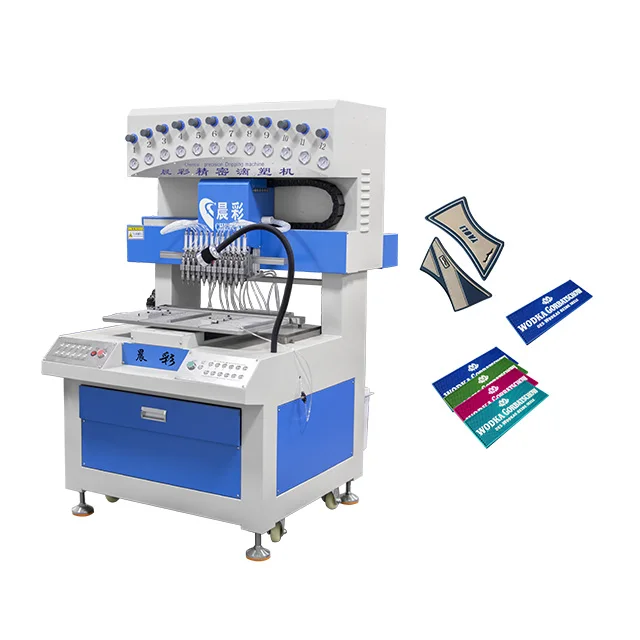

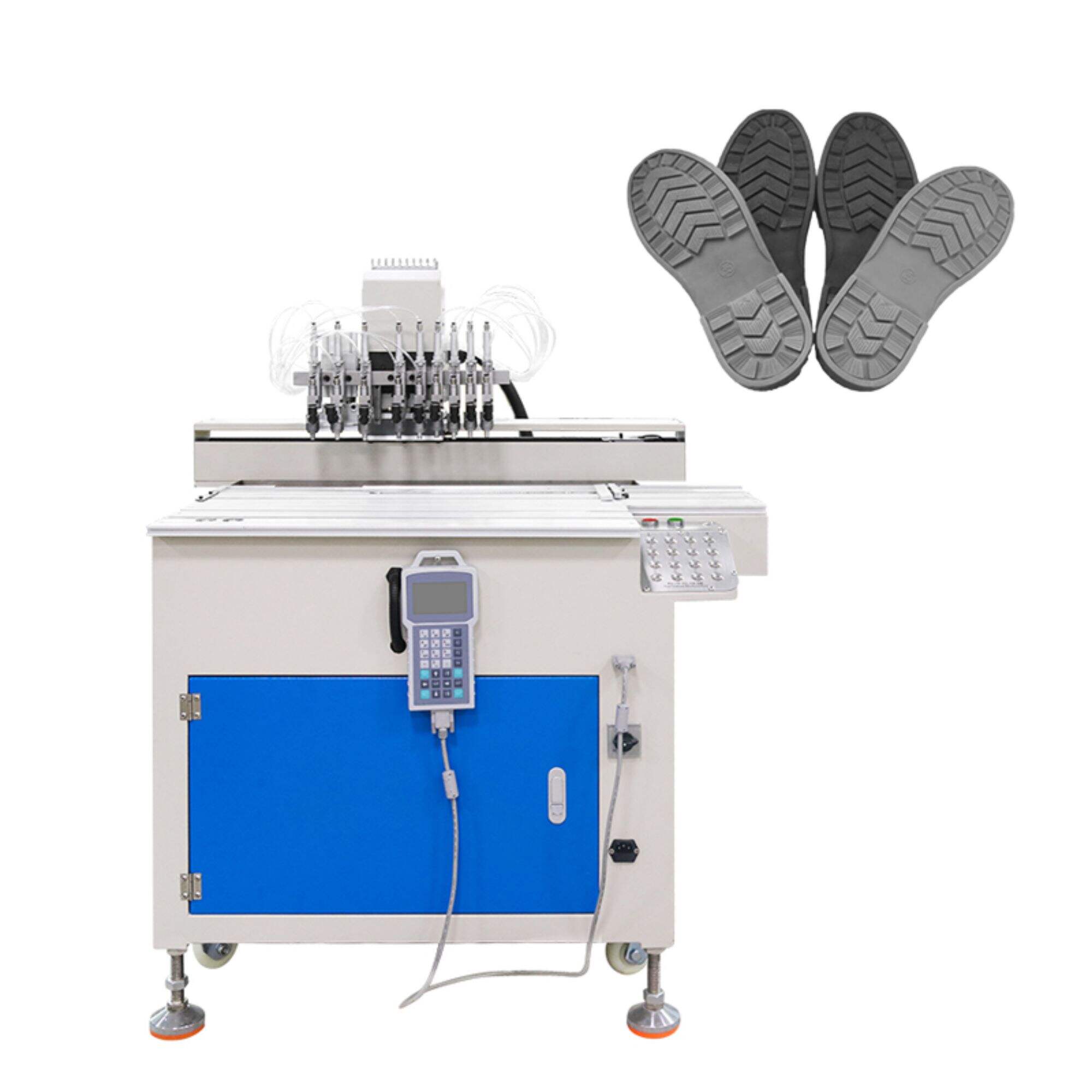

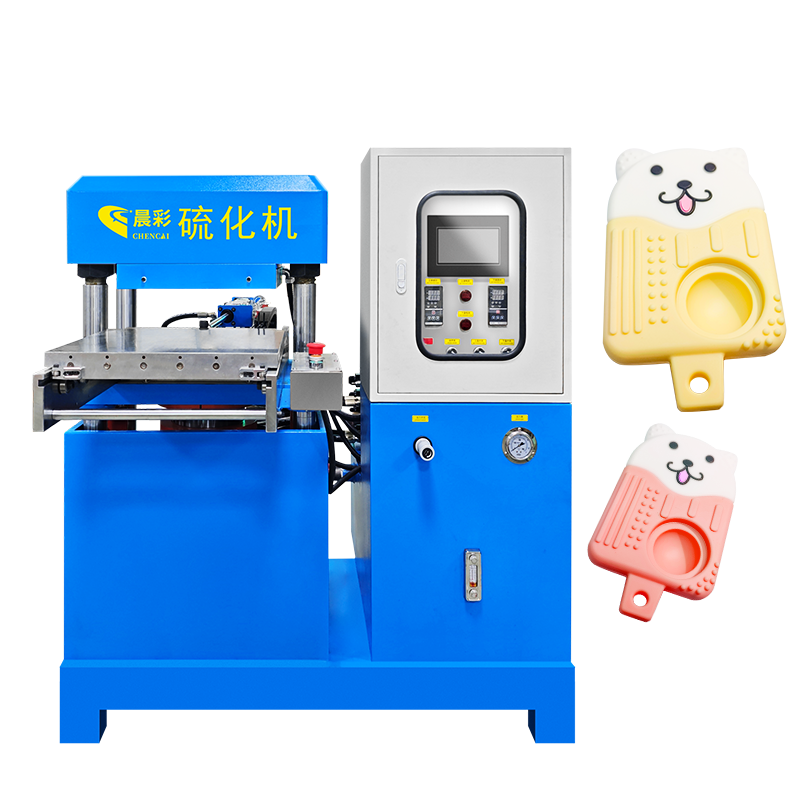

PVC Product Molding: Baking tables facilitate the curing process of the molded PVC products by controlling the heating temperatures and the duration of curing processes ends in uniform heating. When used on assembly lines, these tables provide a working surface for the manual application of adhesives, thus creating enhanced accuracy and reduced adhesive usage.

Manual Adhesive Application: Because of their broad working surface, baking tables are often used for the manual application of glue, thus improving accuracy and reducing material wastage.

Baking Table Innovations at Chencai

Chencai's main goal is to develop the innovation on the baking tables with no boundaries. The industry specific within our product range has several distinctive features:

Advanced heating systems with modern temperature control elements allow to ensure uniform heating within the entire area of the surface. All our baking tables are designed with the environment in mind: only green materials are utilized, but at no cost to the efficiency. Many of them have IoT functionality which allow to change or check a number of parameters through a dedicated application.

Recognizing that one size fits all does not apply here, we provide custom services for the design and production of baking tables as per the client's requirements.

The Key Role of Heating Ovens in Various Industrial Processes

ALLWorking Principles and Performance Optimization of Silicone Rubber Milling Machines

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY