Understanding the Vulcanizing Machine

Working Principles

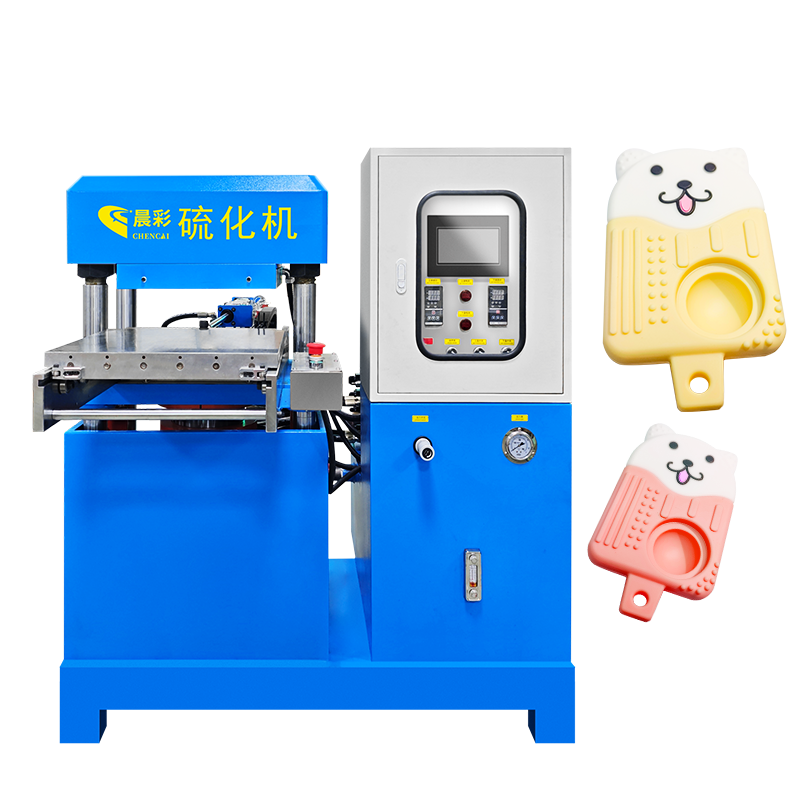

Vulcanizing machine is a unit that functions on the principle of heat and pressure application to the raw material which are essentially rubber or plastic. Consisting of heating chamber where the raw materials are placed, and press that comes into contact with the materials, heat combined with pressure cause chemical reaction known as vulcanization in raw materials. It makes use of heat and pressure to produce cross-links between polymer chains hence increasing its durability, flexibility, as well as resistance to heat and chemicals among other environmental elements.

Types of Vulcanizing Machines

There are various vulcanizing machines available in the market today for specific purposes. Some commonly encountered types include:

1. Autoclave: It is large sized pressure vessel used for high-pressure vulcanization of rubber products such as tires, hoses and other heavy-duty rubber products.

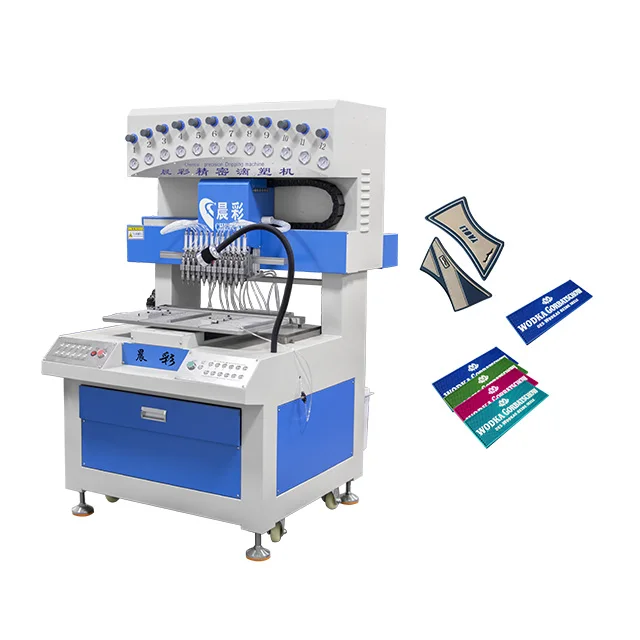

2. Injection Molding Machine: This type of vulcanizer serves in producing complex-shaped rubber articles with high precision. The process combines injection molding and vulcanization into one step leading to high-quality articles having consistent dimensions.

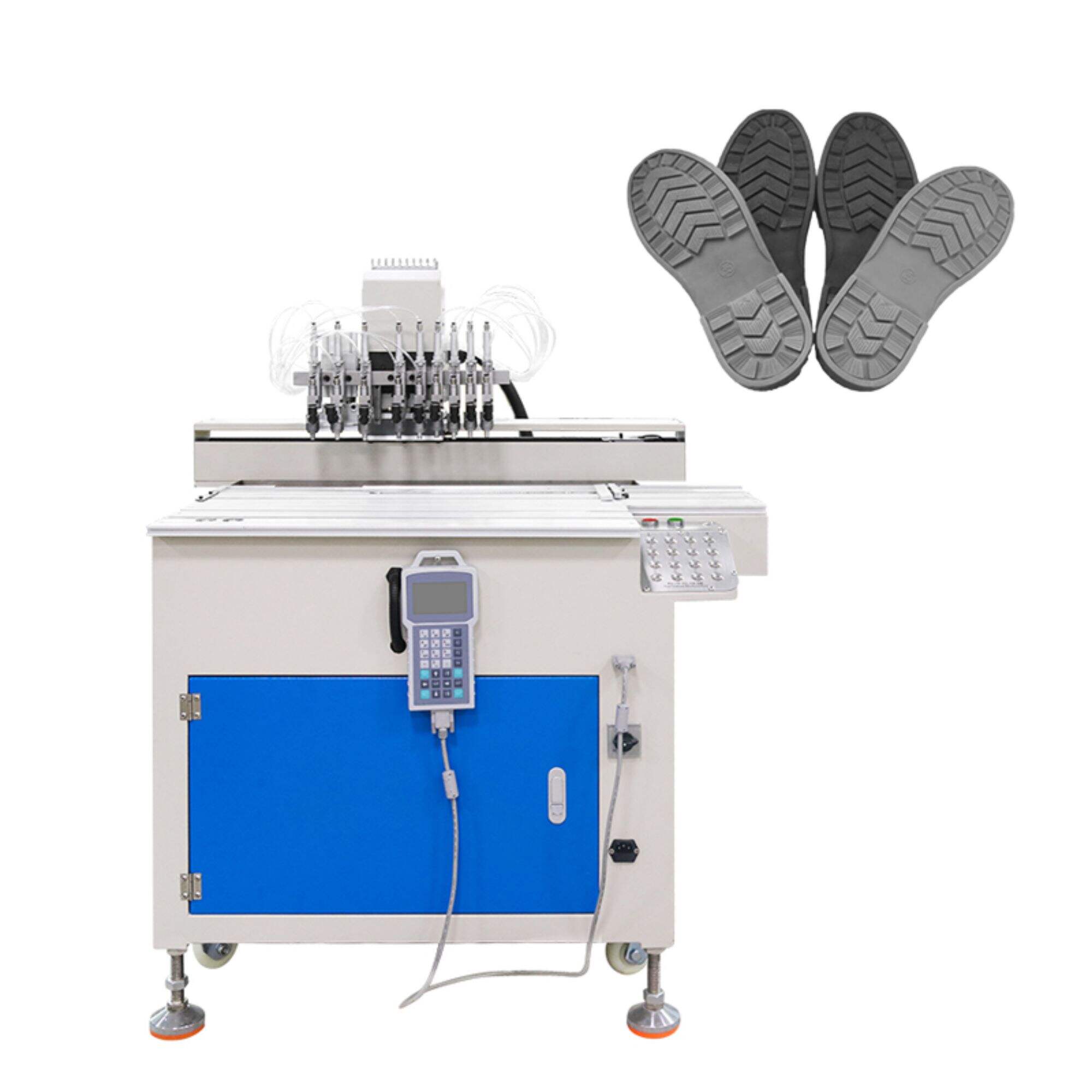

3. Compression Molding Machine: These machines make flat or simple-shaped rubber products like gaskets, mats, seals etc., by applying pressure using a heated mold so that during vulcanizations they take up the shapes of molds.

4.Transfer Molding Machine: A type 0f machine for this purpose produces hollow or intricately shaped rubber articles.

Applications

In various industries including; automotive, aerospace, medical, construction and consumer goods’ production lines extensively employ Vulcanizing machines in their manufacturing processes because they produce a wide range of things (e.g., tires,, hoses belts ) made from these substances: gaskets ,seals ,O-rings ,and many others.

Advantages

The application if vulcanising machines have numerous benefits for manufacturers. Some examples include:

1. Better Quality Products: Vulcanizers ensure uniformity in quality during vulcanisation through the application of specific heat and pressure to the materials.

2. Increased Production Efficiency: Vulcanising machines reduce production time and increase effectiveness by performing multiple steps at once.

3. Cost Savings: By reducing manual labour and minimizing defective products as a result of quality inconsistency, vulcanisers can be a source of cost savings for manufacturers.

Conclusion

The manufacturing industry requires a vulcanizing machine especially in the production of rubber and plastic products. Thus, it is imperative that these devices are chosen with regard to their numerous advantages such as; product quality enhancement, increased production efficiency, cost savings, versatility, among other factors which make them critical tools in supporting maturity of this sector.

The Highly Versatile Power of Silicone Labeling Machines That Can Withstand Weather

ALLThe Cost Considerations of a PVC Tag Making Machine

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY