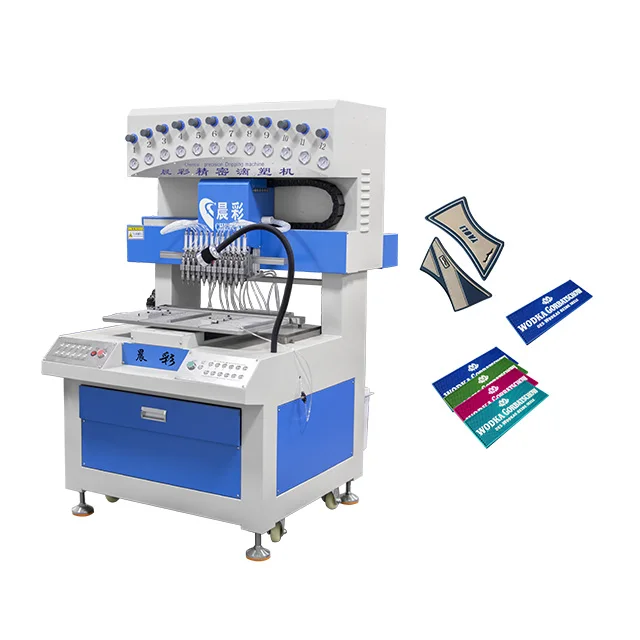

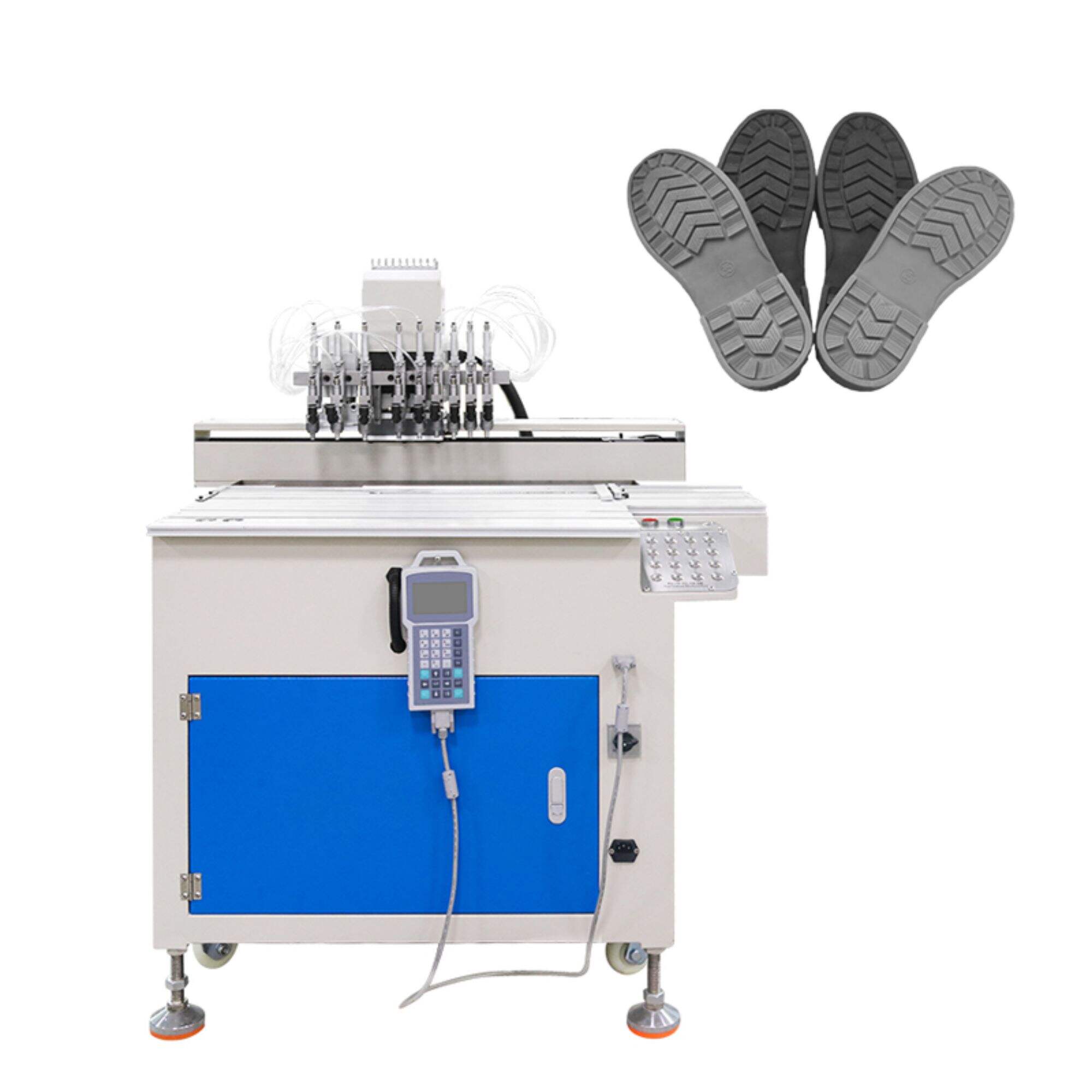

The Cost Considerations of a PVC Tag Making Machine

The Initial Cost of the Machine

A basic PVC tag making machine can come at different prices, depending on the model, brand, and specifications. It might be possible to purchase some machines at as low as 8,500 or even much more. Only know that you are purchasing a device which will meet your manufacturing demands and budget limitations.

Other Costs

Apart from the main cost, there are other costs that should form part of one’s investment as shown below:

1.Shipping and Handling: Shipping and handling charges may contribute to a notable percentage of the overall cost depending on where the supplier is located.

2.Installation: There might be need for professional installation of certain machines thereby making it necessary for extra labor expenses.

3.Training: In case this machine has specific operating procedure then operators may attend special instructions.

Operating Expenses

During operation of PVC tag making machine, one should also consider about those continued costs:

1.Raw Materials: Raw materials that go into production involves PVC tags with additional necessary additives. This means depending on market prices and production volumes; raw materials acquisition costs will vary accordingly.

2.Maintenance: To keep up its performance and lengthen its useful life time, regular maintenance is indispensable to any machinery including this one. Replacement parts, lubricants and maintenance service wages are encompassed here,

3.Energy Consumption: This results in high energy consumption through electricity or any other source used in PVC tag making process therefore it adds to operational expenditures.

Total Cost of Ownership

When determining how much a PVC tag making machine costs, it is essential that all aspects are considered towards total cost of ownership (TCO). This includes everything from initial purchase price through the whole lifespan until disposal comes along with all other related expenditure on it even after bought. For instance if TCO were calculated properly then the investor would have an idea whether his decision was a right one concerning forth coming financial strain.

In summary, the cost of a PVC tag making machine is not just about the base price. There are additional costs to be considered such as operating costs and total cost of ownership. A good understanding of these factors will enable you to make a wise decision that suits your budget and production needs.

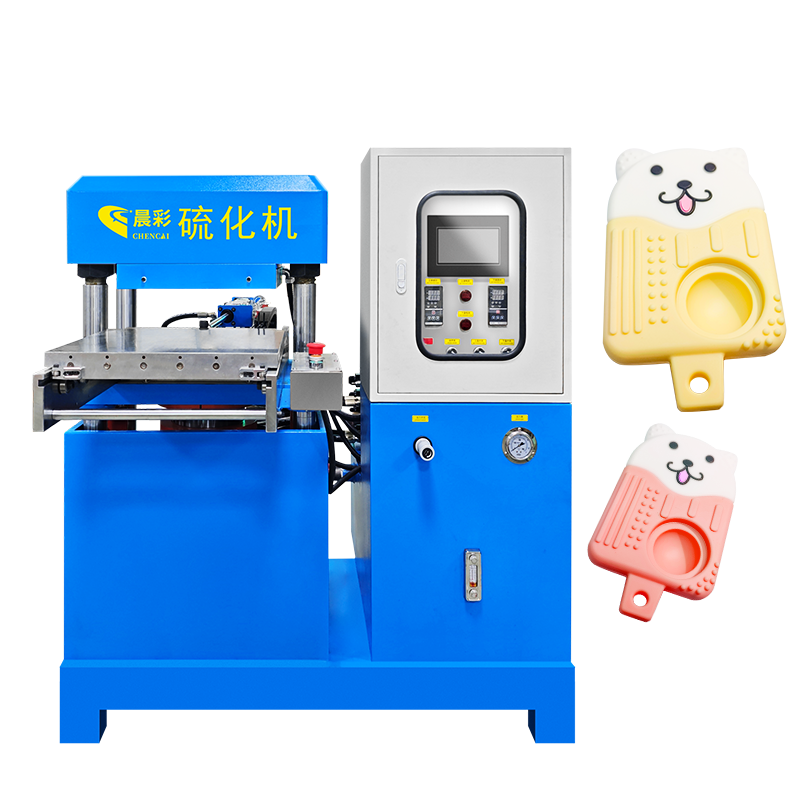

Understanding the Vulcanizing Machine

ALLThe Impact of Stainless Steel Automatic Chocolate Decorating Machines

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY