Understanding The Silicone Rubber Milling Machines

Silicone rubber milling machine is the mainstay of silicone rubber processing in the industrial world. It is a specialized equipment that refines and gives shape to silicone rubbers with many different forms for various purposes in different industries. This article will explain about how this silicone rubber milling machine works and why it is important in modern-day manufacturing.

An Overview of the Silicone Rubber Milling Machine

The advanced technology used in a silicone rubber milling machine makes it a sophisticated piece of equipment. It has blades or rollers that rotate, grind, mix as well as shaping such materials into desired products. Its versatility enables it to handle varied categories of silicone rubbers; which is why this machine has become indispensable to sectors like automobile industry, electronics and medical.

Working Principles for Silicone Rubber Milling Machine

The principle behind operation of the silicone rubber milling machine involves deformation by shear. In doing so, forces are applied on material resulting into its deformation as facilitated by rotating blades or rollers. The resultant outcome will be material being broken into smaller portions hence mixing them up properly within itself for perfect dispersal. This ensures that the material is evenly distributed without contamination thus making a high-value product.

Applications Of The Silicone Rubber Milling Machine

Due to its ability to process silicone rubbers into different shapes, this device finds use in several industries across the globe. In automotive sector, they make seals and gaskets besides hoses that require a lot durability together with heat resistance plus chemical reactions respectively. Electronics industry also uses these machines in order to make silicones used in insulation and isolation from electric shocks when designing electrical components such as connectors etcetera .This appliance also helps medical sector to create things such as artificial limbs among other implants where sterility needs be maintained while maintaining precision.

Advantages of Silicone Rubber Milling Machines

Compared to traditional ways of processing silicone rubbers, there are many advantages associated with using silicone rubber milling machines. This machine is highly effective which means it saves a lot of time during fabrication hence reduces labor costs. Moreover, it allows for processing of large quantities of materials hence maintaining uniformity and reducing the possibility of making mistakes. Additionally, this device can be tailored to suit specific needs; thus, making them suitable for different applications.

Silicone rubber milling machine is a cornerstone in modern manufacturing by providing an efficient and dependable method of manufacturing silicone rubber products with varying shapes. These features, together with other aspects like its versatility and ability to produce high standard items have given this equipment a permanent place in many industries. As technology continues to advance we should anticipate more innovative uses as well as better versions of these milling machines in silicon rubber in future.

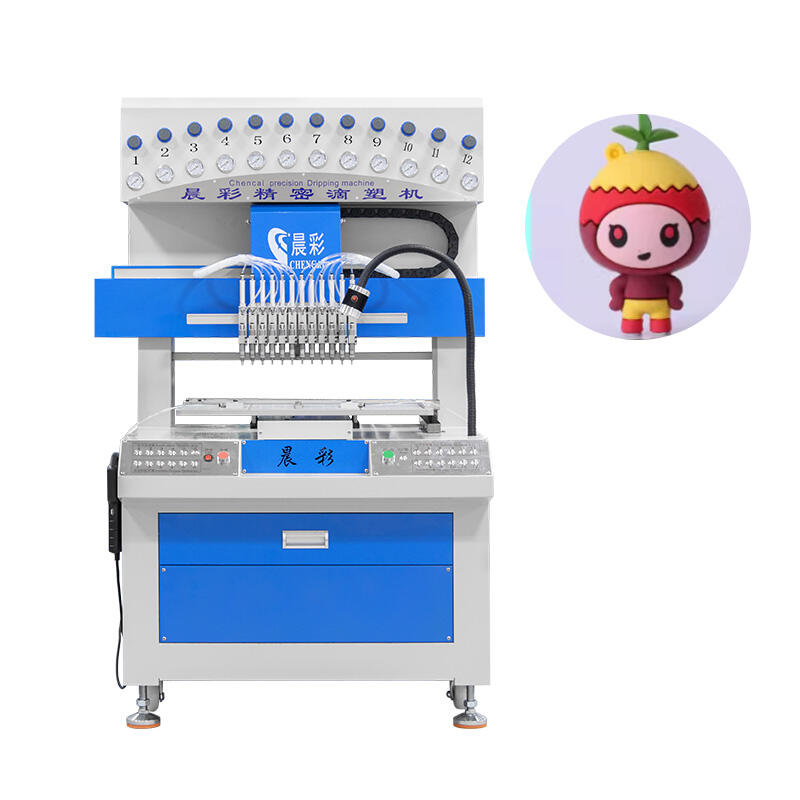

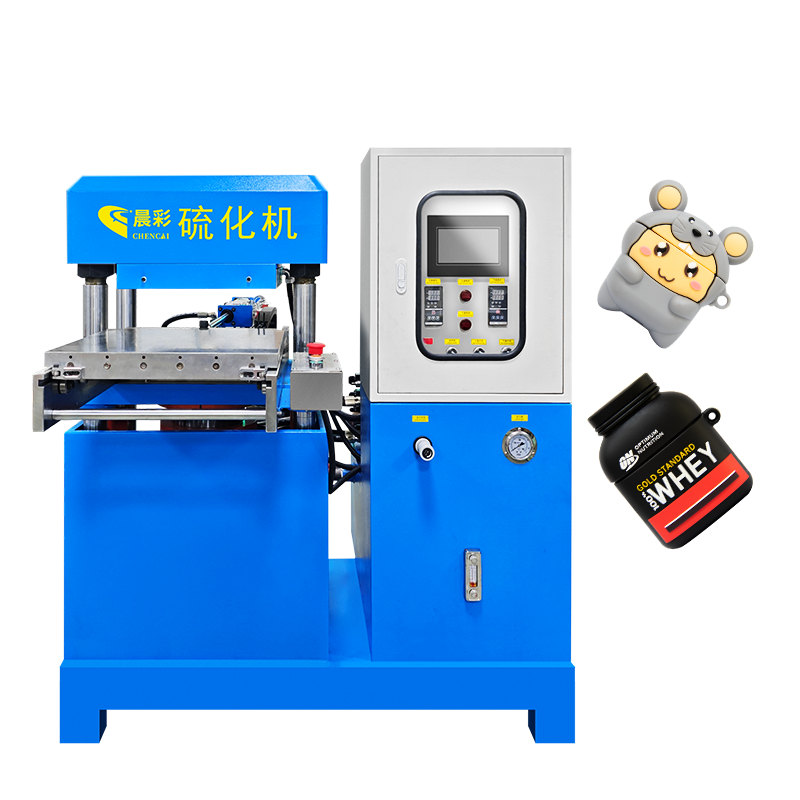

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY