The Important Functions Of The Heating Ovens In Manufacturing

Manufacturing is responsible for the creation of almost everything we use on a daily basis including automobiles, electronic devices, food items and pharmaceuticals. The making procedure is comprised of machines, materials and technologies that are used to produce these goods. These sectors use heating ovens due to their critical roles in delivering quality products and safety.

Heating ovenswhich are also referred to as industrial ovens are specialized tools that heat up, bake, dry or cure substances. They play an important role in the manufacturing industry especially for the production of foodstuffs, plastics industry electronics and automotive amongst other industries. They can be adjusted to exact temperatures and they have advanced features which enable effective energy management.

In the bakery sector for example, heating oven is essential when it comes to cooking breads as well as pastries. This guarantees consistent baking and destroys harmful bacteria that could cause disease through contaminated foods. On the same note in meat production poultry farming uses ovens for cooking smoking or curing these increase flavor while prolonging shelf life.

The plastics industry is heavily dependent on heating ovens during the curing process. During this last process step in composite production, resin matrices undergo hardening at elevated temperatures leading to achieving their final properties. Such products include fiberglass reinforced plastic (FRP) composites used for construction purposes such as laminates in car parts or marine applications.

Heat treatment processes carried out in electronics manufacturing require heating ovens just like soldering or adhering using adhesive material requires heat curing; drying printed circuit boards (PCBs). Maintaining specific temperature levels during these procedures ensures high quality findings throughout. Inadequate warming leads to poor performance by producing cold solder joints as well as improperly cured substrates thus damaging electronic devices reliability.

Paint curing on motor vehicles happens within paint booths with help of baking machines among others such as combination infrared/air heaters rendering liquid paint into solid finish coats resistant to abrasion, corrosion and all the other weathering actions. At the same time, after assembly processes, ovens are used for curing adhesives and sealants used in automotive assemblies which help in maintaining structural stability.

Over the years, heating ovens have undergone significant changes in their designing and engineering. Modern industrial ovens have advanced controllers including programmable logic controllers (PLCs) that enable operators to set accurate temperature profiles and monitor them. Additionally, energy saving features like thermal insulation and recirculation systems have been incorporated to reduce energy consumption as well as operational expenses.

Moreover, safety measures are integral in the design of industrial ovens. For instance an emergency stop switch with interlocking doors can be employed on such type of equipment while explosion proof designs could also be utilized.

Heating ovens are a vital component in many manufacturing operations. They play a critical role in product quality assurance, safety regulation as well as facilitation of chemical processes through maintenance of temperature levels. These indispensable contrivances will grow even more sophisticated due to technological advancements making sure that our manufacturing industry keeps up with changing times.

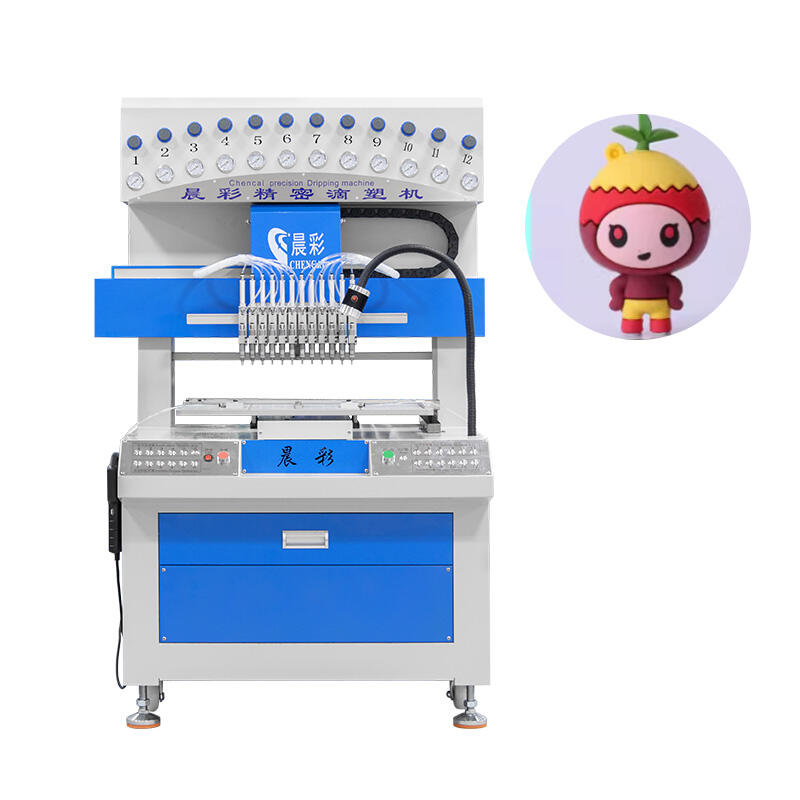

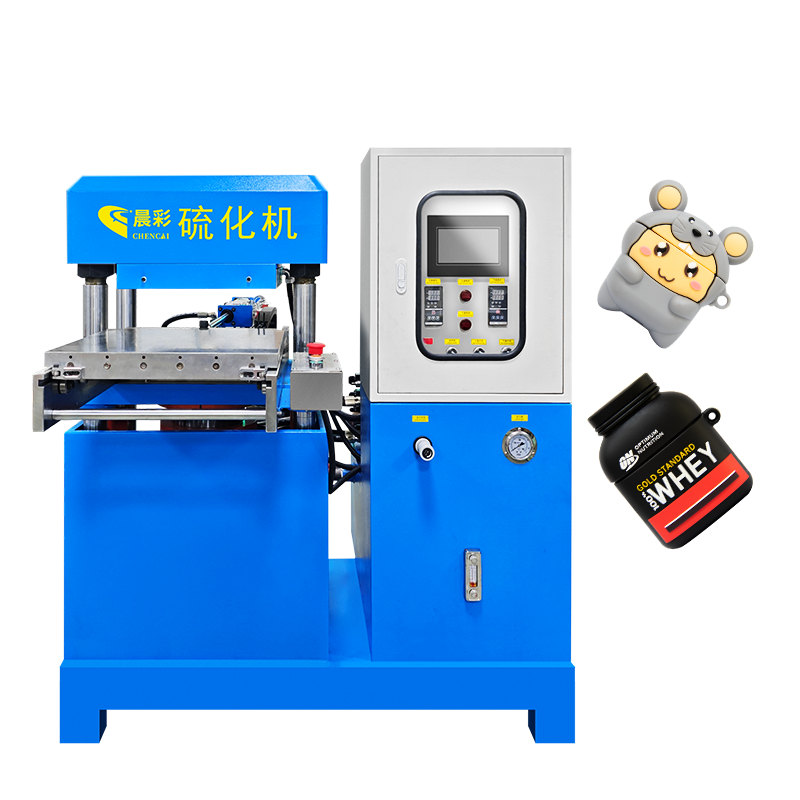

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY