What is the cost of PVC tag making machine?

As far as manufacturing and branding are concerned, customized tags are invaluable to companies that want to improve their products’ character and professionalism. Among the many materials used in the manufacture of tags, Polyvinyl Chloride (PVC) stands out due to its resilience, versatility, cost-effectiveness. The machine is specifically designed for making PVC tags more efficient.

In most cases, a PVC tag making machine is made up of several crucial parts that promote quality production:

1. Material Feeding System: This facilitates a smooth flow of PVC material into the machine and can be adjusted so that it allows different sizes and thicknesses of PVC sheets.

2. Printing Mechanism: Depending on whether quantity or quality takes precedence thermal or inkjet printing systems can be installed here to put written words or pictorial representations or barcodes on the surface area of the produced plastic cards.

3. Cutting System: In other instances under consideration is this precise cutting system which may employ sharp blades or laser technologies for accurate cuts enough to fit specific shapes in which case they are required.

4. Software Interface: With such an interface one can make a design template for his/her tag(s), set the necessary program(s) for his/her machinery and therefore manage production process in totality.

5. Finishing Options: Other options include adding laminating features, holes punchers for hangings among others.

Several factors determine how much a PVC tag making machine costs:

1. Machine Complexity: Generally, sophisticated machines with high levels of automation will cost more than basic models will.

2. Production Capacity: Purchasing machines that are built for higher volumes may come at more expensive prices compared to those suited for low volume manufacturing processes.

3. Brand and Quality: Renowned brands often fetch premium prices for reliable and durable machines.

4. Additional Functions: However, if a machine can do more such as multi-color printing, die-cutting or built-in quality inspections this will add to the cost price.

5. Market Conditions: In addition, the price may be determined by market forces such as demand, availability of raw materials and location.

The current market prices for PVC tag making machines range from a few thousand dollars for basic models to tens of thousands of dollars for high-end industrial grade ones. Therefore, it is necessary to consider specific requirements and make a budget before buying one.

Moreover, total cost of ownership should account not only for the initial purchase cost but also include maintenance fees, replacement parts and other consumables like ink or print ribbons.

In conclusion, PVC tag-making machines are an investment worth considering by businesses that want to streamline their tag production process. By evaluating these factors against its abilities manufacturers will come up with an informed decision which suits their production needs as well as their financial targets.

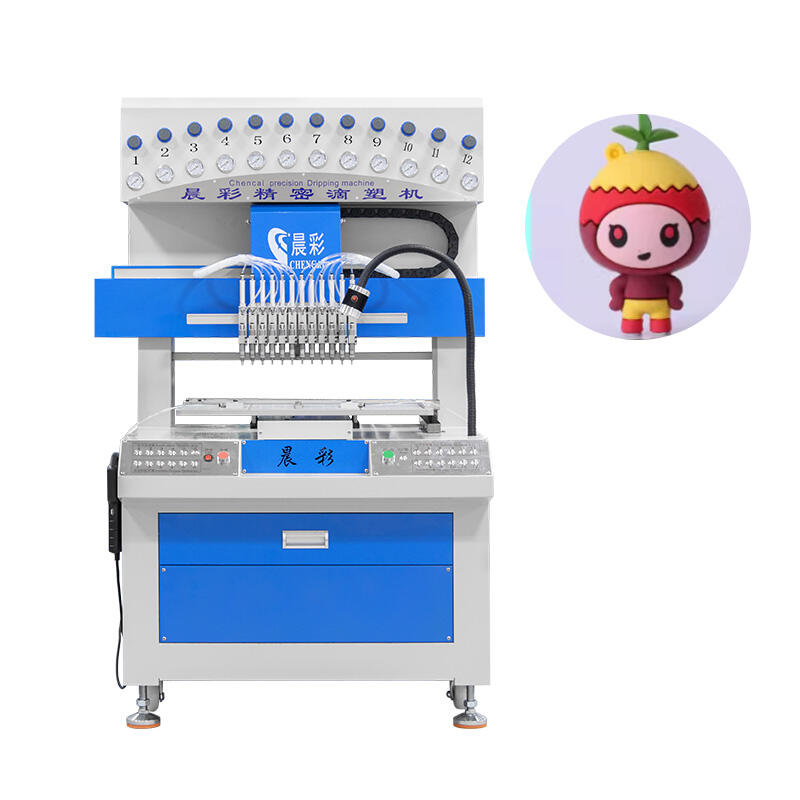

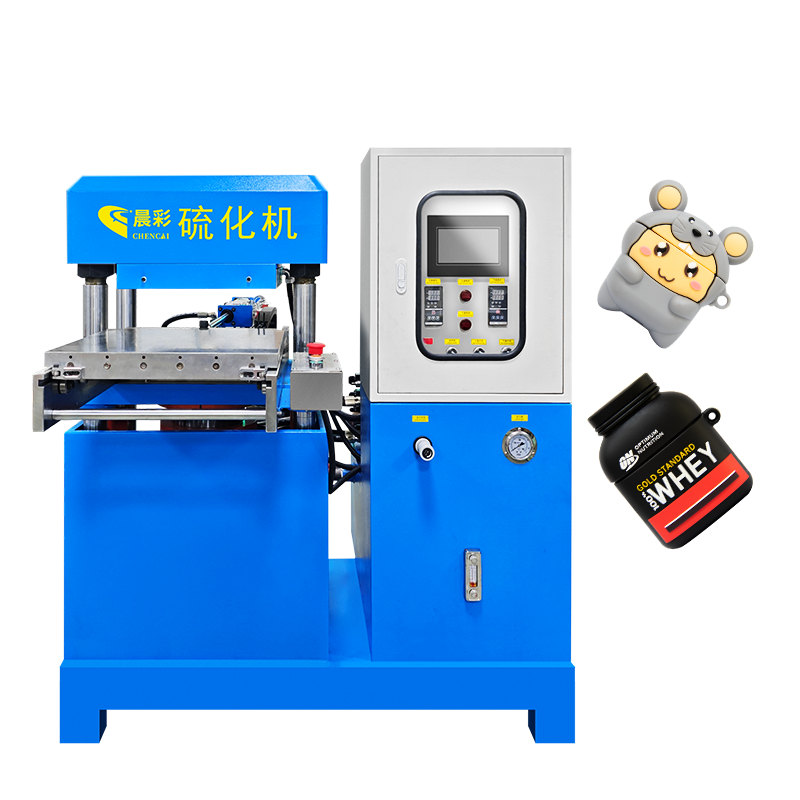

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY