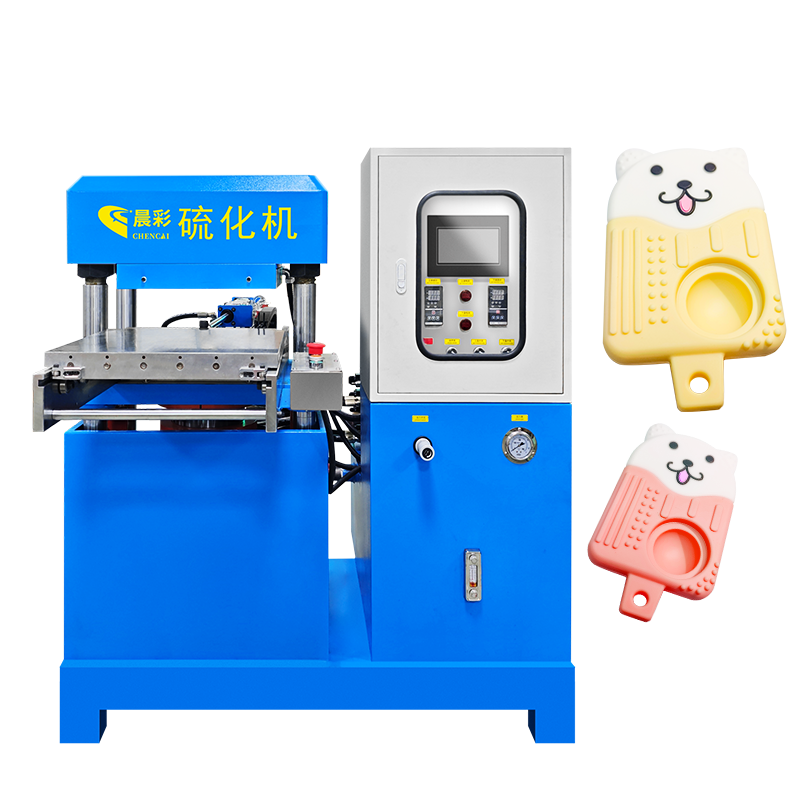

What is a vulcanizing machine?

Principles of Vulcanization

Polymer chains in rubber or plastic are bonded through vulcanization, which is one way chemical process. The latter’s proceeds under the action of sulphur or other vulcanizing agents. The machine allows for uniform application of heat and pressure that leads to effective vulcanization reaction on materials hence enhancing their elasticity, tensile strength against heat and chemicals among others.

Components and Structure of the Vulcanizing Machine.

A typical vulcanizing machine comprises a heated platen, a system of applying force, as well as controls. The heating plates constitute the main working surface on which materials are placed for curing/gingerly. Electrical elements or alternative heating methods are employed in achieving desired temperatures at this location. The force application unit may be hydraulic or pneumatic thereby facilitating uniform distribution during pressurized processing while control unit enables setting up as well as monitoring temperature levels, amount of pressure exerted together with timing required for particular products during adsorption/vulcanization cycles.

Applications of Vulcanizing Machine

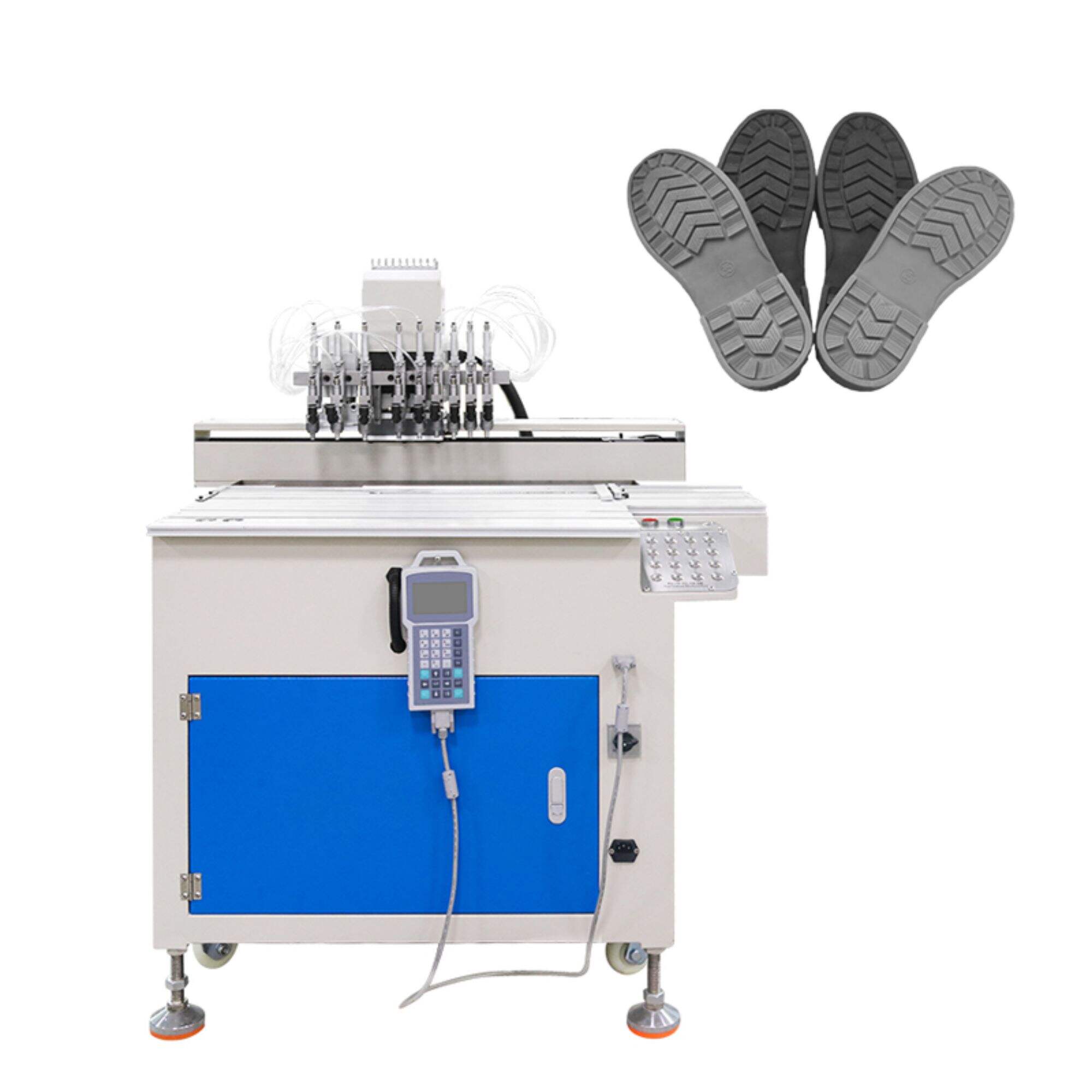

The use of vulcanizer is widespread across different sectors throughout various industries. In automobile industry, it helps produce tires, seals and gaskets out of rubber material. Footwears such as shoes comprise parts made from materials that have passed through curing processes using this critical industrial equipment. Apart from these applications in footwear manufacture over there is also usage in electrical insulation materials production like hoses cables belts etcetera where they get integrated by blending their basic making components with several additives including curatives accelerators stabilizers retarders modifiers fillers plasticizers cross linking agents and colourants for achieving the desired properties depending on specific functional requirements of each product group.

Advantages of Vulcanization

Vulcanizing machine offers several benefits in the manufacturing process. Firstly, vulcanization enhances the physical characteristics of rubber and plastics to ensure they are stronger and more resilient. These qualities result in products that last longer even under tough environmental conditions and when under heavy use. Secondly, vulcanization allows forming complex shapes and structures which could not be formed using un-vulcanized materials. This consistent strength is achieved through uniform application of heat and pressure across all sections of molding plates during manufacture.

In summary, a vulcanizing machine is an important equipment used in manufacturing industries for producing long lasting rubber or plastic goods of high quality. The effective cure carried out by this machine converts raw materials into functional parts with increased physical properties. As such, it can be deployed in different sectors from motor industry to footwear because it has been designed with versatile features that make it useful across various fields. The vulcanizing machine has experienced significant technological advancements that have made them more accurate as well as efficient within production processes unlike before

A Breakthrough in Weather Resistant Silicone Labeling Machine

ALLStainless Steel Automatic Chocolate Decorating Machines Unveiled

NextRecommended Products

Hot News

-

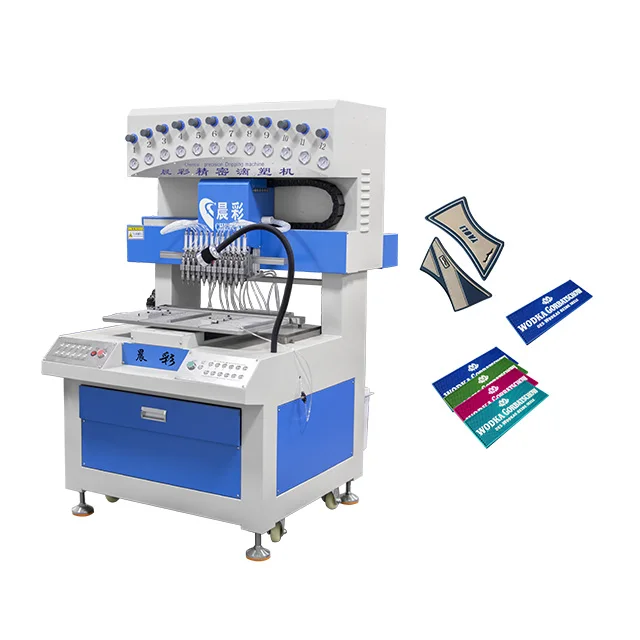

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY