The Power Of 3D Press Molding Machines In Manufacturing

There is a revolution happening in the manufacturing industry due to the introduction of 3D press molding machines. These modernized machines are capable of changing raw materials into intricate and precise components within seconds, hence, they are a necessity for any plant or industry.

Manufacturers prefer to use3D press molding machinesbecause they have numerous advantages. The first one is that these machines make it possible to manufacture components containing intricate designs and complex geometries. Traditional molding methods cannot produce such detailed parts but with 3D press molding machines, this is possible due to their high level of precision. This ensures that the parts not only work as expected but also comply with the stringent manufacturing standards.

These machines are faster and more efficient than traditional methods of molding is another benefit associated with them. In contrast to traditional types, 3D press molding machines produce within a short span. Consequently, reducing production time and costs involved increases efficiency in terms of higher production rates with minimized workforce requirements that enhance productivity and profitability in return. Furthermore, this means that the company has shorter turnaround times which are important in meeting customer needs and maintaining competitiveness.

Furthermore, 3D press molding machine is needless flexible plus it allows for customization. They can be easily adjusted to produce a wide range of components with different shapes, sizes, and materials. This flexibility allows manufacturers to quickly adapt to different production requirements characterized by new product launches or last minute design changes. The capacity of customizing parts according to specific clients’ needs creates room for innovation by producers hence differentiation from other market players.

Another aspect other than their functionality of these equipment in comparison with others such as autoclaving, injection molding among others is they offer an eco-friendly alternative for conventional manufacturing processes as well plus forward thinking companies should consider this reality too when investing on industrial tools presently available on the markets worldwide today.. It employs less materials, reduces wastage and is energy efficient compared to the other conventional molding techniques. The efficient use of materials and energy translates into cost savings and a reduced environmental footprint. It also helps manufacturers meet the growing demand for sustainable and environmentally friendly production methods from customers and stakeholders.

Integration of 3D press molding machines in manufacturing processes enhances collaboration and communication among different departments within the organization. They enhance close cooperation of other departments such as product development, engineering, design and production through their presence in these sections hence facilitating idea exchange as well as feedback on the process throughout its phases. As a result, this enables firms to generate fresh concepts that will lead to better decision making aimed at streamlining the process of manufacturing.

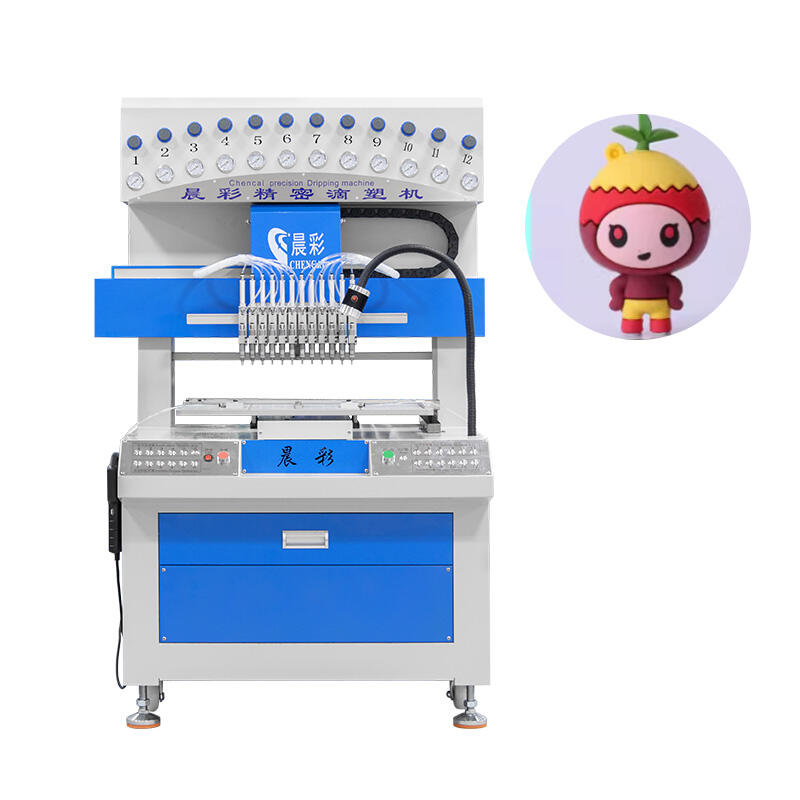

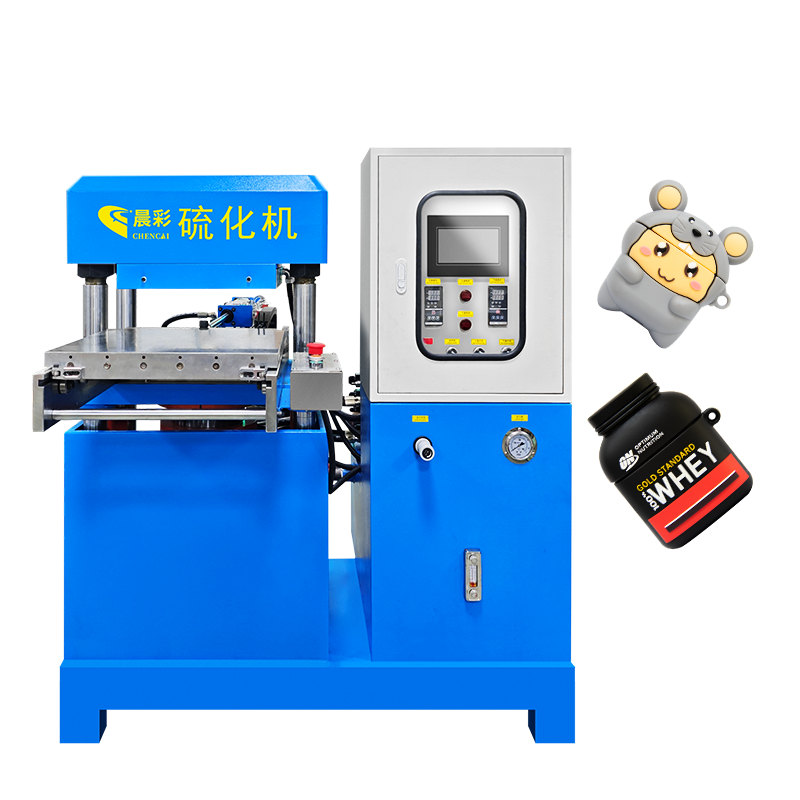

Recommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY