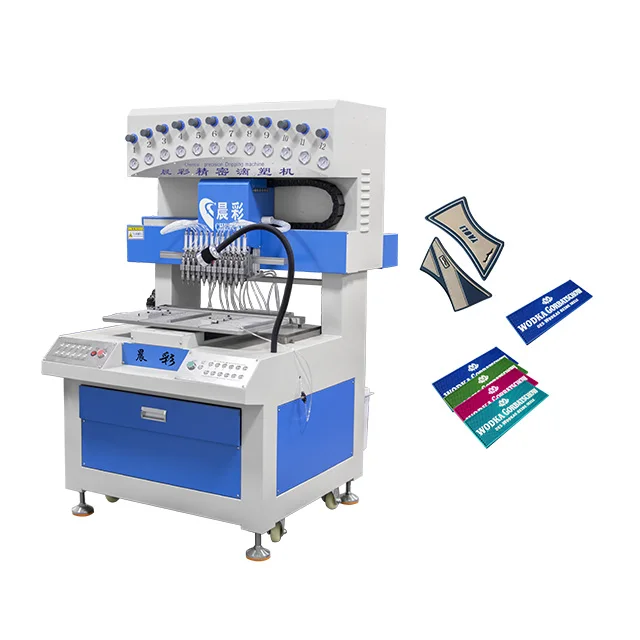

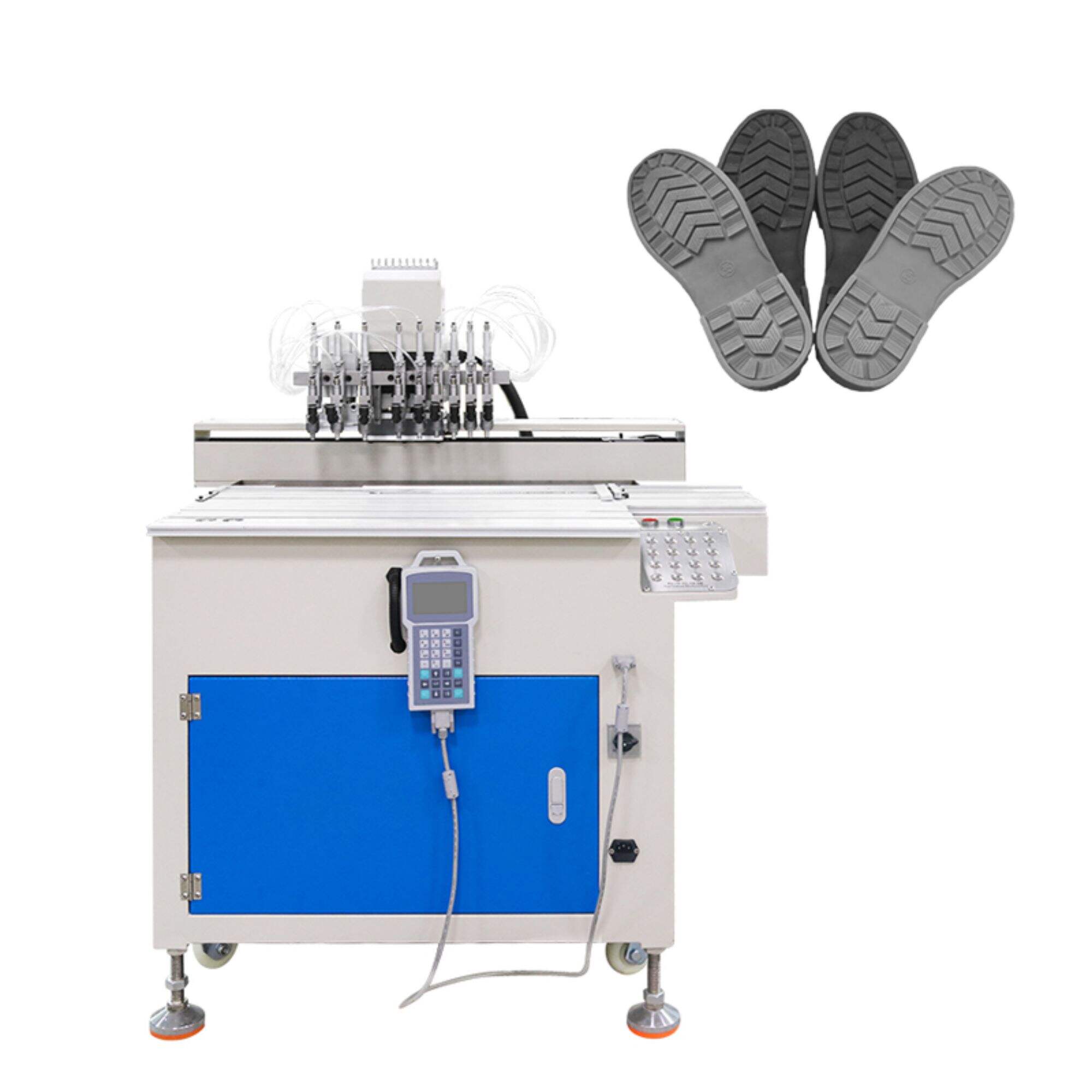

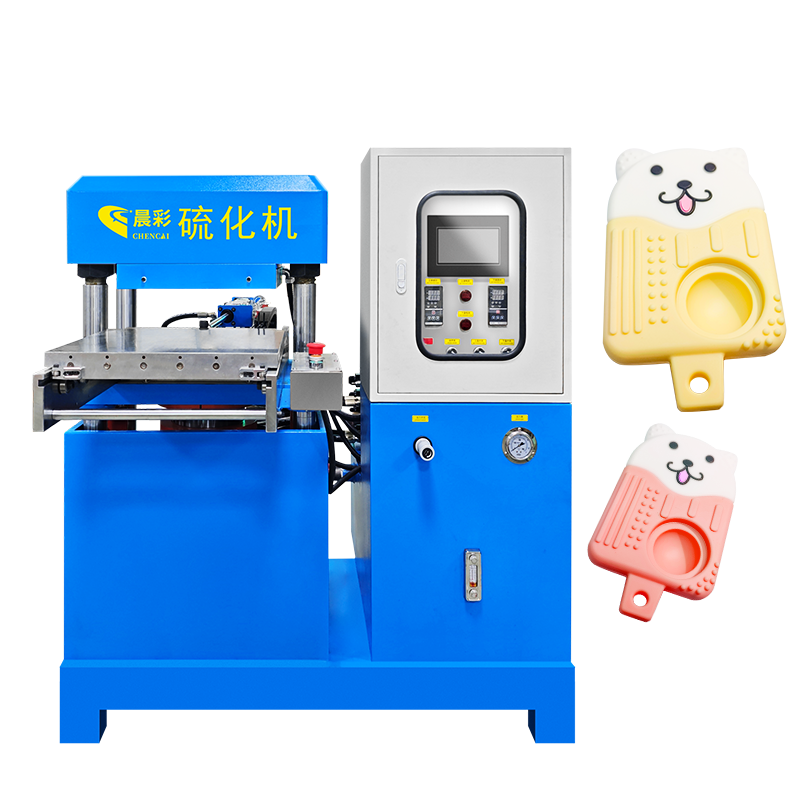

The Advantages of PVC Dispensing Machines

PVC Dispensing Machines have become a game changer in the manufacturing industry as PVC products are transformed. These machines being automated provide several advantages that greatly increase production and enhance product quality. The paper examines the key benefits of PVC Dispensing Machines on industrial production.

1. Efficiency Increase

These include PVC dispensers that streamline the production process by eliminating manual intervention and reducing human error rates. These devices have control over how PVC is injected into a mold. Hence, they ensure consistent results which are correct leading to enhanced overall efficiency. They manufacture more products within less time hence meeting market demand effectively.

2. Higher Precision

Most notably,PVC Dispensing Machinesdistinguish themselves through excellent precision delivering capabilities. For this reason, these devices use sophisticated technology to regulate PVC material flow so as to avoid wastage and ensure accurate measurements. With uniform dimensions and desirable properties, constant exactness in PVC disbursement produces high quality items.

3. Better Quality Products

The automation of the dispensing process for PVC has greatly contributed to improved product quality by these machines. This eliminates human mistakes such as uneven distribution of materials or inconsistent speed of injection thus allowing production of flawlessly final goods. By this means, each product is made to meet precise specifications thereby increasing its overall quality and customer satisfaction.

4. Cost Reduction

PVC Dispensing Machines offer cost-saving benefits in multiple ways.Firstly, the automation reduces the need for manual labor resulting in reduced labor costs.Secondly, minimal wastage of material by these machines makes them assist in optimal utilization of resources in a way that saves costs.Additionally, manufacturers can fulfill more orders within a shorter time due to increased productivity brought about by these machineries thereby having potential for increased returns.

5.Flexibility And Adaptability

Designed for wide product requirements, PVC Dispensing Machines accommodate different production needs.These machines facilitate production of diverse PVC products because they can accommodate a wide range of mold sizes and shapes. This option allows a business to meet new markets and expand its product base.

Conclusion

PVC Dispensing Machines have emerged as game-changers in the manufacturing industry, offering numerous advantages that boost productivity and improve product quality. Consequently, PVC product manufacturers cannot do without these machines as they achieve increased efficiency, more precision, better product quality, reduced costs, flexibility. The adoption of this advanced technology does not only streamline production processes but also position companies strategically making them succeed in the ever-changing market environment.

Transform Sweets With A Chocolate Decorator Machine

ALLSilicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY