Revolutionizing the Rubber Industry: The Role of Vulcanizing Machines

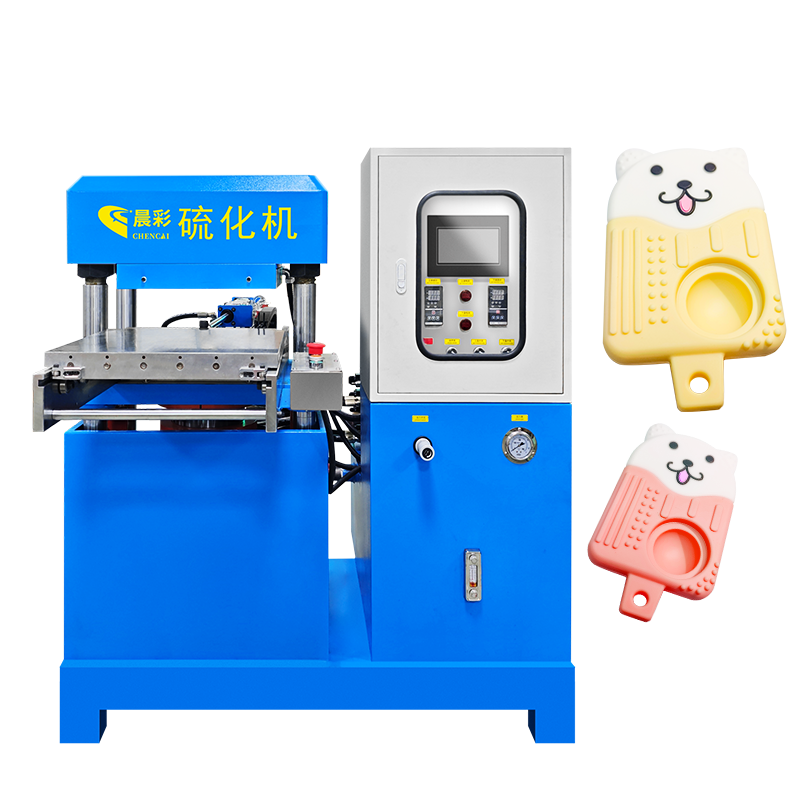

Vulcanizing machine is a key instrument in the field of rubber production, converting raw materials into hard-wearing and versatile goods. This modern equipment plays an important part in vulcanization process by which rubber molecules are linked together to increase elasticity, strength, heat resistance and chemical resistance.

The vulcanizing machine works by applying heat and pressure to the rubber mixtures, thereby initiating the reaction that cements its molecular structure. Through this procedure, not only does the physical properties of the rubber get improved but also its lifespan increases making it applicable for various uses such as automotive tires, household items among others.

One of the major benefits of using vulcanizing machines is that they offer consistent and uniform results each time. These machines have accurate temperature and pressure controls which ensure that every batch of rubber goes through similar treatment thereby resulting in uniformly homogeneous products with superior qualities.

Additionally, vulcanizing machines are designed to handle different types of rubber compounds thus supporting diverse formulations and specifications. This way producers can serve different market demands ranging from ordinary rubber items to dedicated commodities made specifically for certain industries.

Moreover, demand for these devices is increasing as global market for vulcanizers expands since numerous industries require elastomeric goods. In addition to higher efficiency levels as well as an environment-friendly approach characteristic of present-day equipment used in this sector; these contribute towards its productivity and profits.

In summary, without it then there would be no high grade effective rubbers that we use daily hence it is core thing in the industry. It allows compounders materialize their dreams of having best rubbers through proper vulcanization techniques. For evolving players in this sector, the future hinges on what they will do with their aging vulcanizers.

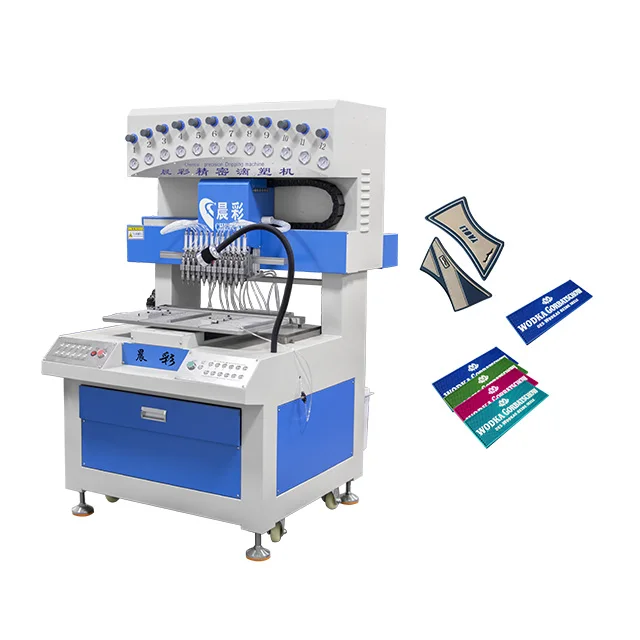

The Versatility of Weather Resistant Silicone Labeling Machines

ALLThe Role of PVC Tag Making Machines in the Manufacturing Industry

NextRecommended Products

Hot News

-

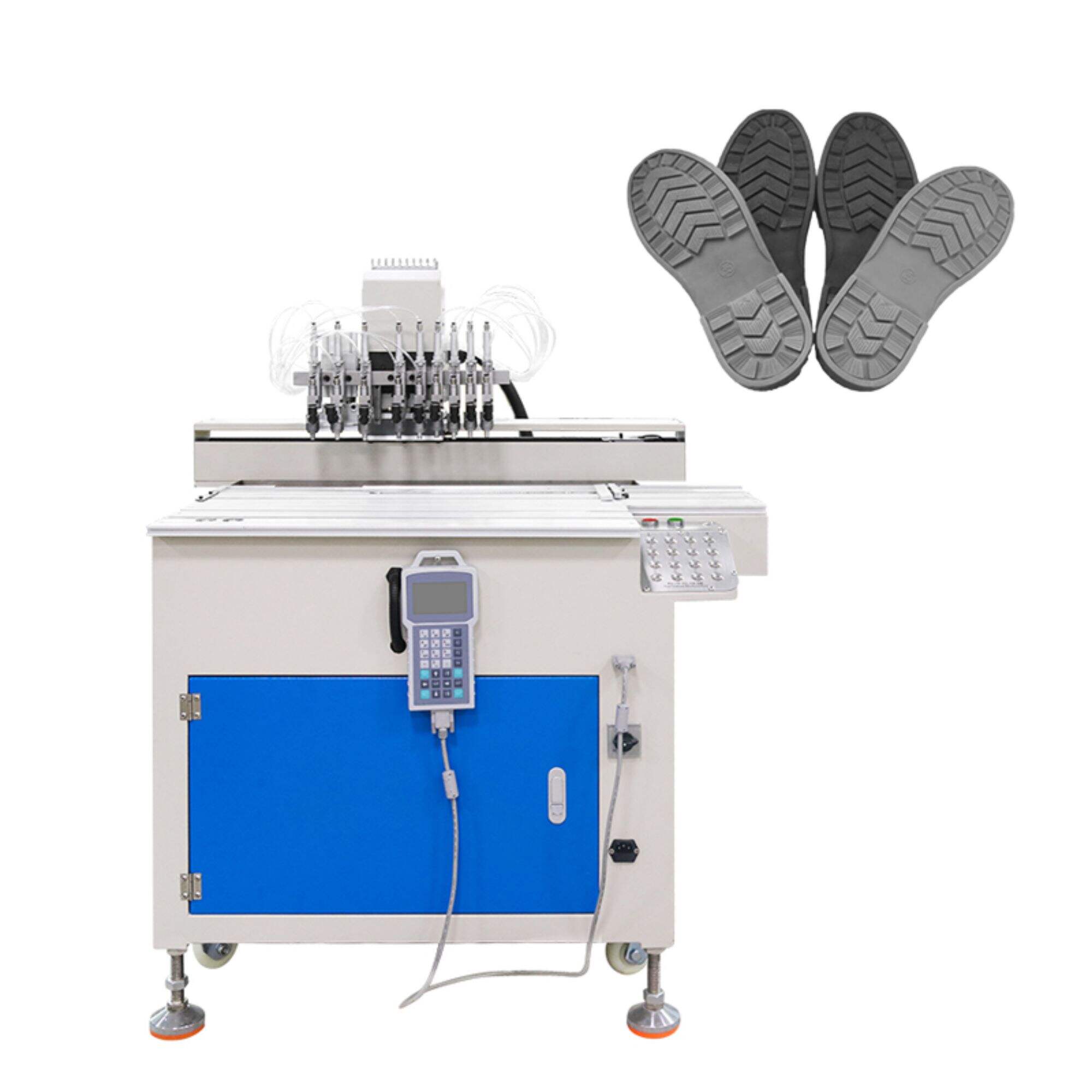

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY