Multi-functional Application and Maintenance Related to Sand Blasting Machines

1、Multi-functional Application

1.1 Surface Preparation

Surface preparation is one of the main functions of sand blasting machines. They are widely used for the cleaning and preparing of surfaces for painting, coating or bonding. Removing previous paint, rust and other impurities provides sand blasted surface which is clean and rough and exclusive for bonding of coating for durability of the coating.

1.2 Restoration Projects

In restoration processes like automobiles or architecture restoration works, sand blasting machines are of great usage to return surfaces to original form. It is also easy to use a sand blaster on wood, metals and even stones to get rid of rust, old paints, or any other attached stains.

1.3 Etching and Engraving

Sand blasting machines can be applied particularly for etching designs into surfaces for artistic or industrial applications. There are occasions when the intricate patterns or designs are needed and surfacing works is done with this technique.

1.4 Finishing Touches

The decoration of products and components can be done concurrently with the stiff state of a composite material through the use of sand blasting machine. sand blasting machine can effect sme internal surfaces of a product with required finishes such as non glossy.

2、 Maintenance Tips

It is necessary to keep the sand blasting machine healthy and make it operational for a longer duration by frequently performing its maintenance routine. So, let’s move on to essential maintenance procedures.

2.1 Regular Cleaning

You have to clean the sand blasting machine completely after each use in order to eliminate remnants of the abrasive material used. This avoids any blockages and enables the device to operate efficiently. Most especially, the nozzles and hoses should be carefully cleaned.

2.2 Check for Wear and Tear

Examine all parts for damages on a timely basis. Damages Here means: change out defective items to prevent any more serious faults or delay to production capacity. This involves the checking of the away material, the nozzles and seals.

2.3 Lubricate Moving Parts

The accurate lubrication of the moving parts of the blasting system is very important to the working of the sand blasting machine and also contributes to its longevity. Adhere to recommendations pertaining to the kinds of lubricants used and their frequency in application.

2.4 Store Properly

At no time when the sand blasting equipment is not being called upon must it be left in an area that is excessively wet and dusty Sweeping Dry Her Around, there are no hazardous elements such as moisture or dust that could result in rusting and other problem.

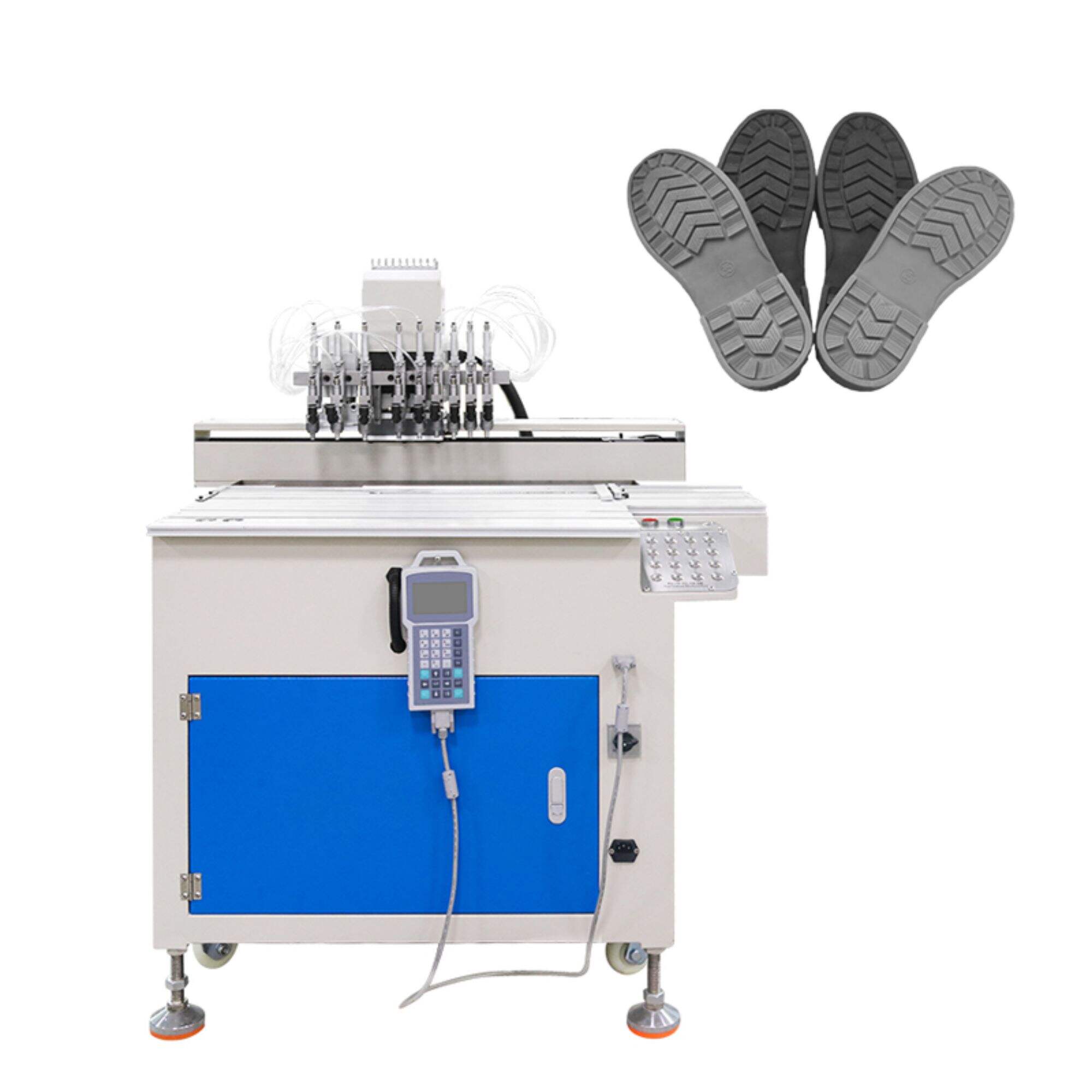

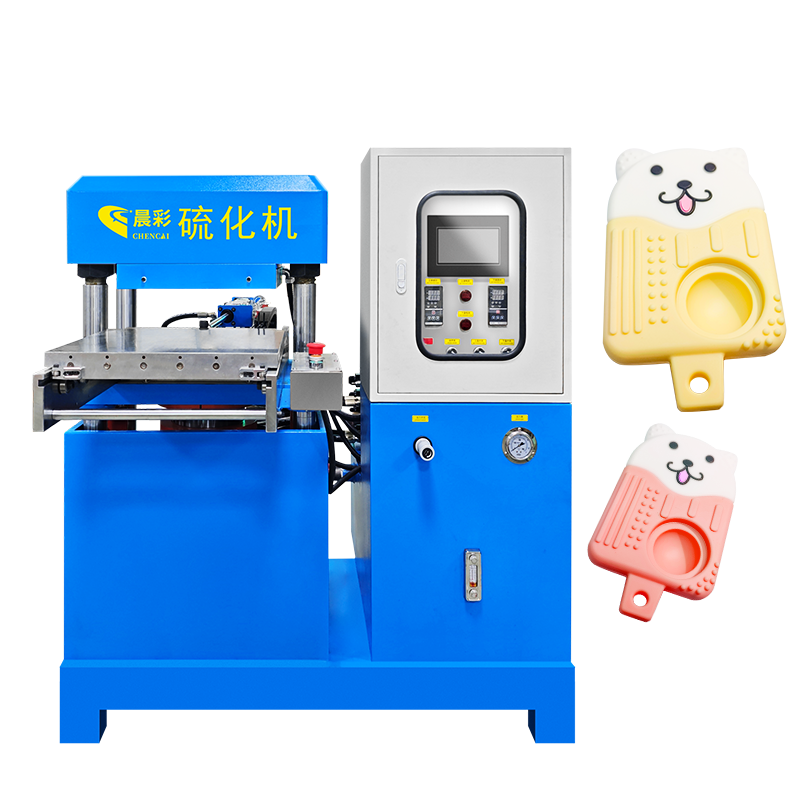

Applications and Advantages of 3D Press Molding Machines in Manufacturing

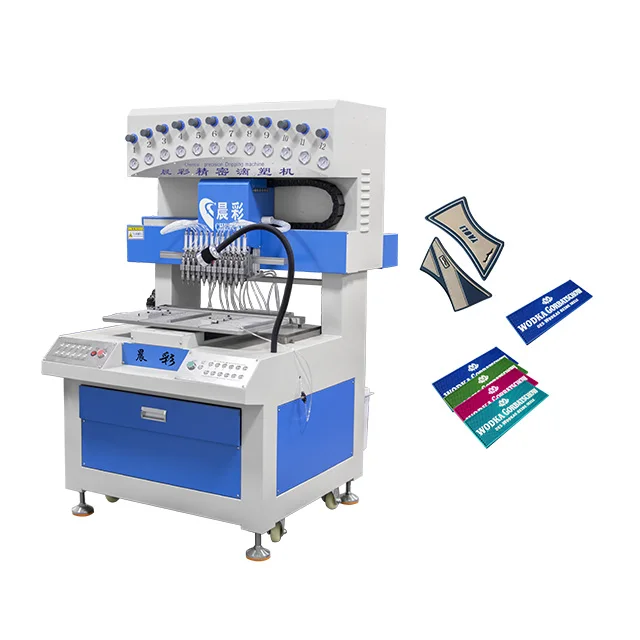

ALLApplications of Silicone Label Machines in the Industry of Apparel and Accessories

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY