Application and advantages of silicone dispensing machine in high-precision manufacturing

Understanding the Role of Silicone Dispensing Machines in Precision Manufacturing

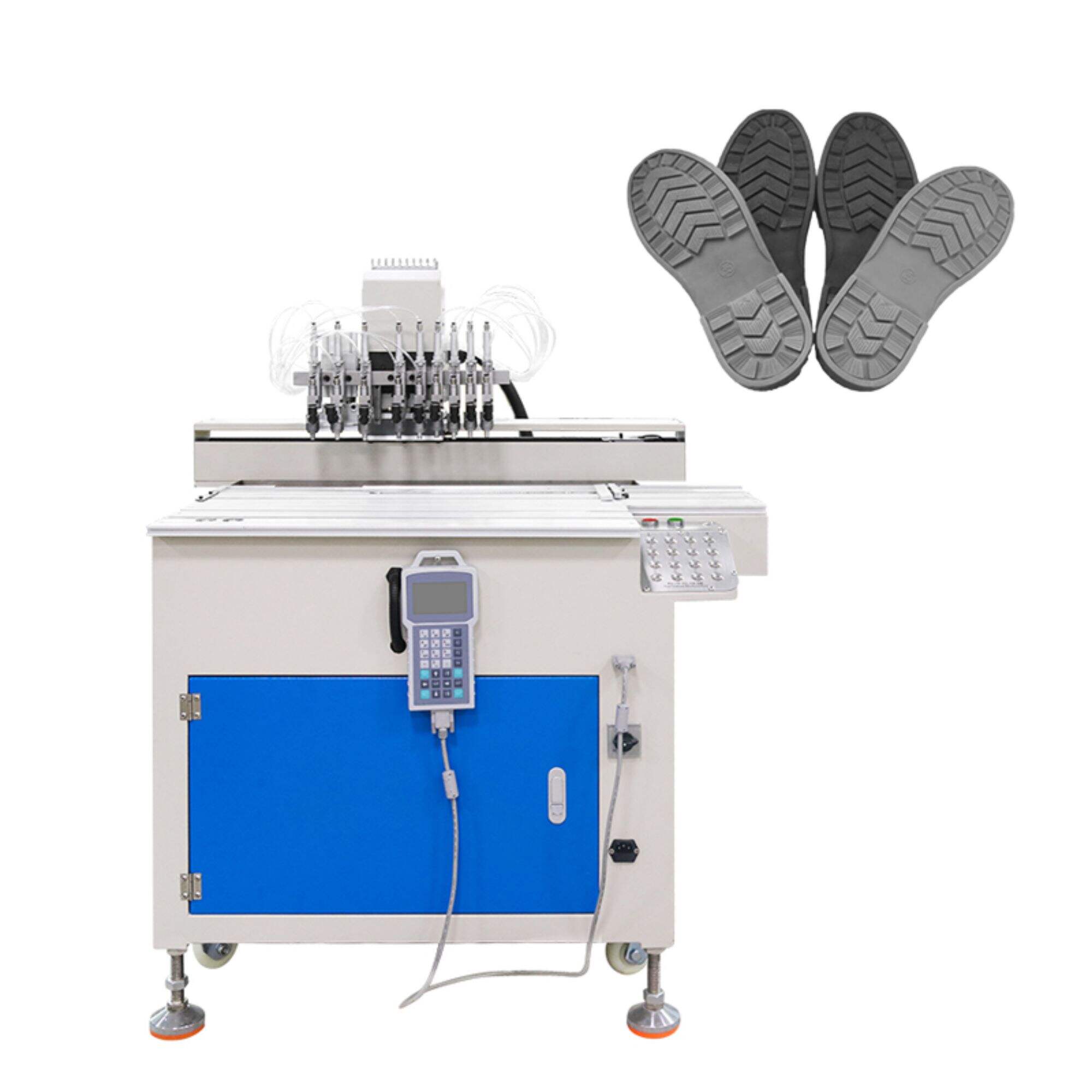

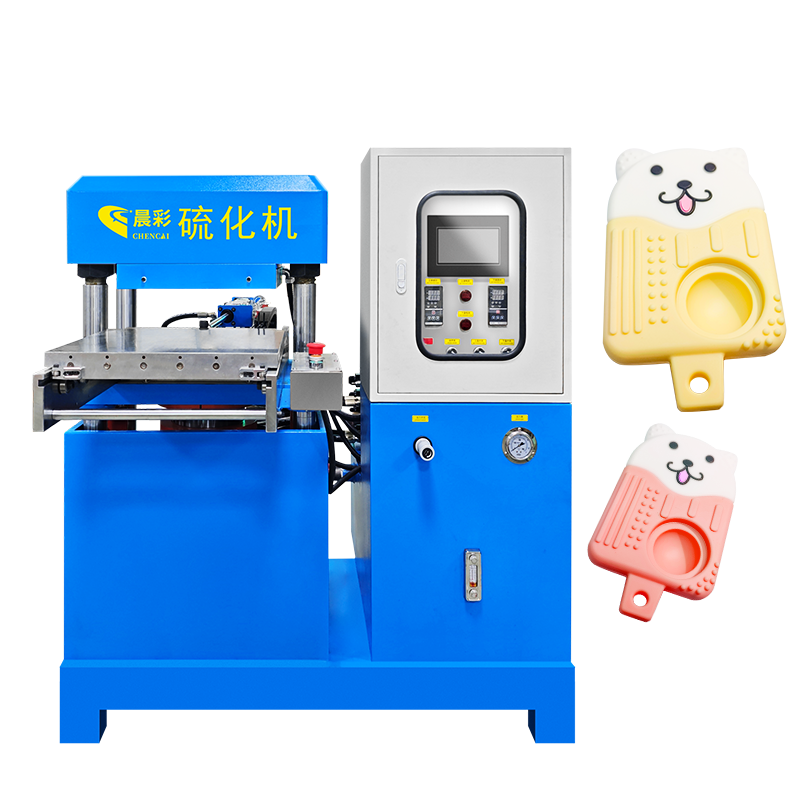

Silicone dispensing machines are critical tools in manufacturing, primarily designed to manage the accurate dispensing of silicone materials. They consist of intricately calibrated mechanisms including storage tanks, nozzles, valves, and pumps. These components work together to precisely deposit silicone onto various surfaces or substrates, crucial for crafting products such as gaskets, kitchenware, toys, and more. The programmable nature of modern machines allows them to maintain consistent operational parameters, ensuring uniformity and precision in mass production settings.

Precision in manufacturing is vital for delivering high-quality products, and silicone dispensing machines are instrumental in achieving this level of accuracy. By allowing for exact control over silicone flow and deposition, these machines significantly reduce material waste and enhance efficiency. For example, in the production of silicone phone cases, the precise application ensures the material covers necessary areas without excess, improving product quality while optimizing resources. This capability underscores their indispensable role in modern manufacturing processes, where precision is synonymous with success.

Advantages of Using Silicone Dispensing Machines

Silicone dispensing machines significantly enhance production efficiency by streamlining the workflow and reducing downtime through automation. By automating repetitive tasks, these machines help minimize human error and fatigue, leading to smoother production lines. For example, in factories that produce high volumes of silicone gaskets, the use of these machines allows for continuous operation without the need for frequent breaks or manual intervention. This not only speeds up the production process but also ensures a consistent output, thus optimizing overall efficiency.

Furthermore, these machines are instrumental in improving product quality by ensuring consistency in the application of silicone materials. They are designed to dispense precise amounts of silicone, adhering to exact specifications that are crucial in various manufacturing applications. Whether it's for applying silicone in automotive gasket manufacturing or intricate patterns on phone cases, the precision offered by silicone dispensing machines ensures uniformity and a high standard of product quality. This ability to maintain consistency across all production units is vital for maintaining a competitive edge in the market.

In terms of cost-effectiveness, silicone dispensing machines are a wise investment that can lead to reduced material wastage and long-term savings. Manufacturers have reported a significant decrease in wasted materials thanks to the machine's precise dispensing capabilities, which ensure that only the necessary amount of silicone is used for each task. Additionally, the longevity and durability of these machines mean that businesses can save on maintenance and replacement costs. This makes them a cost-efficient choice for manufacturers looking to enhance both process and product without significant financial outlay.

Key Applications of Silicone Dispensing Machines

Silicone dispensing machines are pivotal in consumer goods manufacturing, streamlining production processes for a variety of products. For example, in the toy industry, these machines are used to apply soft silicone grips on toys, ensuring safety and durability. In kitchenware, they facilitate the creation of intricate designs and non-stick coatings on silicone baking molds. These machines are essential for maintaining the high standards of durability and aesthetic appeal that consumers expect in the competitive market.

In the automotive industry, silicone dispensing machines are indispensable for sealing and insulation components. They precisely deposit silicone gaskets and seals, which are crucial for preventing leaks and enhancing heat resistance. The automotive sector frequently uses these machines to create parts like silicone hoses and vibrations dampers, which must meet exacting performance standards. By ensuring consistent application, these machines help manufacturers uphold stringent quality control measures.

In electronics assembly, silicone dispensing machines play a critical role in potting and encapsulation processes. They are used to protect sensitive electronic components from moisture, dust, and vibrations. The machines precisely apply silicone over circuit boards, ensuring complete coverage and reliable protection. This encapsulation is vital for the longevity and functionality of electronic devices such as smartphones, where reliability is paramount. Overall, silicone dispensing machines enhance not only the efficiency of production but also the quality and durability of the final electronic products.

Types of Silicone Dispensing Machines

Silicone dispensing machines come in various types, tailored to specific operational needs. One popular type is thedesktop silicone dispensing machine. These machines are compact, making them ideal for small-scale operations. Typically used in workshops or small businesses, they offer exceptional precision in applications such as custom jewelry creation or personalized silicone molds. An intuitive control panel allows users to adjust parameters, ensuring consistent results. Their portability and user-friendly design make them perfect for hobbyists and small businesses alike.

In contrast,industrial silicone dispensing machinesare quintessential for large-scale manufacturing. These machines are equipped with large reservoirs, enabling continuous high-volume production, crucial for industries like automotive and electronics. Advanced automation features, including programmable controls, allow for complex, precise dispensing patterns across large quantities. This capability is vital in factories where consistency and speed are paramount, such as in the production of silicone gaskets or medical devices. The integration with factory systems further enhances efficiency, reducing manual intervention and ensuring quality.

Featured Silicone Dispensing Machines

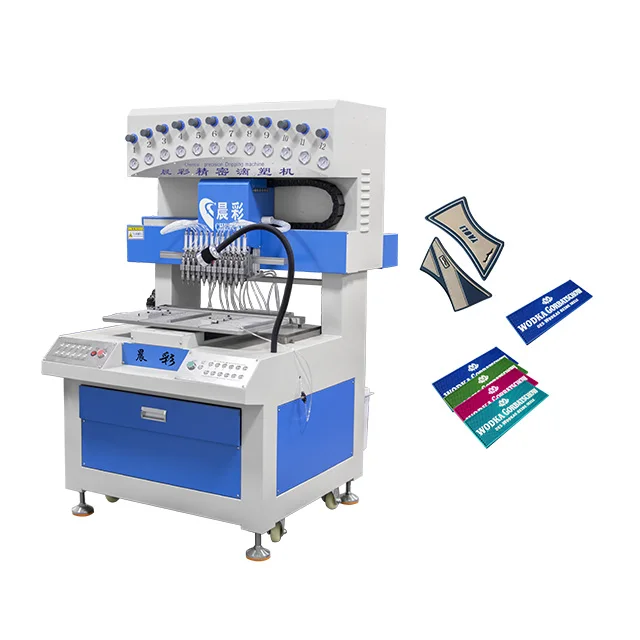

The12 Colors Silicone Dispensing Machine PVC Keychain Machineis a versatile tool for industries ranging from advertising to fashion. It boasts a spacious working desk and high XYZ accuracy, making it suitable for precision tasks. The machine allows for the dispensing of multiple colors simultaneously, which simplifies operations and enhances efficiency. Moreover, its fast speed and excellent injection performance make it a valuable asset for complex production lines.

TheEnlargement Style 18 Colors PVC Silicone Dispensing Machinestands out with its enhanced capacity and operational speed. It's designed to facilitate the dispatch of numerous colors in a single operation. The machine is particularly beneficial in industries that require flexibility and precision, such as electronics and garment manufacturing. It supports fast and efficient production, which is ideal for scaling operations while maintaining quality output.

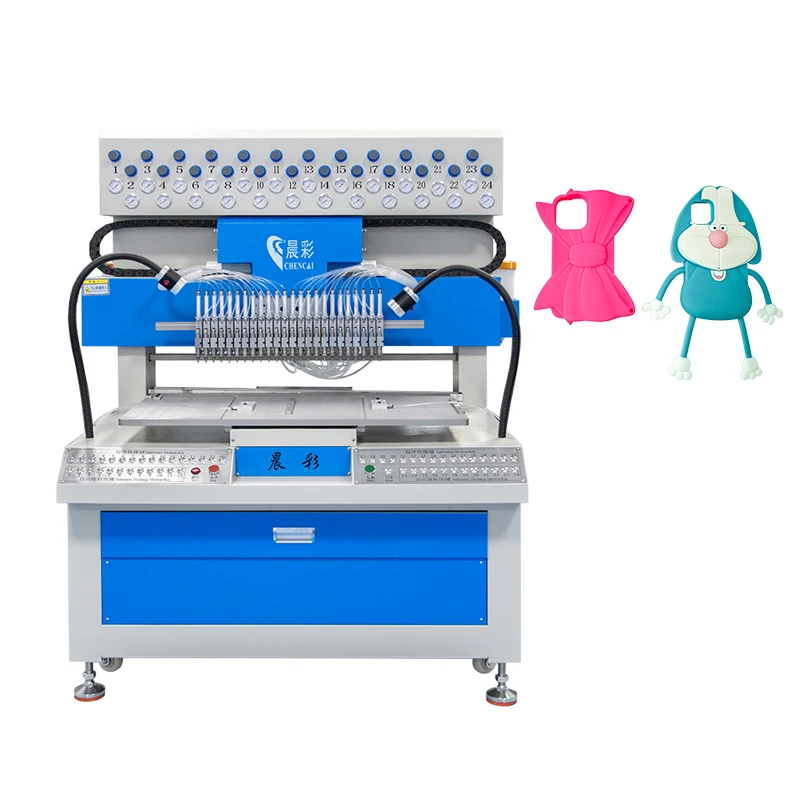

Lastly, theSoft PVC Silicone Dispensing Machine with 24 Colorsis celebrated for its adaptability across various industries such as electronics and automotive accessories. With the capability to operate with multiple colors simultaneously, it ensures high efficiency and excellent dispensing quality. This machine is particularly suited for projects requiring detailed and vibrant outputs, contributing to cost-saving measures through its labor-efficient design.

Conclusion: The Future of Silicone Dispensing Machines in Manufacturing

The future of silicone dispensing machines in manufacturing looks promising, driven by continuous technological advancements. Emerging trends include enhanced automation, precision control systems, and environmentally sustainable designs. These innovations are set to revolutionize manufacturing processes, increasing production flexibility and reducing material waste. Advanced silicone dispensing machines equipped with AI technology might predict maintenance needs or optimize material usage, thereby minimizing downtime and maximizing efficiency.

The impact of these machines on overall manufacturing efficiency cannot be overstated. Industry experts forecast that next-gen silicone dispensing machines will significantly boost production speeds and improve product quality. By automating complex tasks traditionally performed manually, these machines reduce human error and labor costs. As manufacturers increasingly adopt these advanced technologies, they will likely see improved turnaround times, enabling them to meet growing consumer demands with greater ease and precision.

Technical development and innovation trend of PVC dispensing machine

ALLKey factors to consider when selecting a heating furnace

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

IW

IW

EN

EN AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SK

SK UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS GA

GA BN

BN BS

BS MY

MY KK

KK UZ

UZ KY

KY