How does a portable sand blaster work?

A portable sand blaster is used to clean, smoothen, or prepare surfaces by blasting them with a high-speed jet of abrasive particles usually sand. This tool has many applications across various industries such as automobile, construction and manufacturing where it removes rusts, paints and other coatings as well as prepares surfaces for painting or welding.

It is relatively easy to understand how a portable sand blaster works. Generally, it consists of an air compressor, abrasive gun, hose pipe and blast media store. The compressor provides compressed air which forces the grit through the hose and out of the blasting nozzle.

The following are some step-by-step instructions on how to use a portable sand blaster:

Preparation of Abrasive Media:

Firstly, fill up the reservoir with media (usually sand) or whatever material you have chosen for your application like glass beads or aluminum oxide. What kind of material used depends upon desired finish and type of surface being blasted.

Operation of Compressors:

Switching on an electrically driven machine or activating pneumatically operated one will power up the compressors that produce highly pressurized air stored in pressure tanks or fed down the tube to the nozzle.

Delivering Abrasives:

Depressing blasting buttons allows compressed air to move from tubing picking up grains from chambers they are kept in at rest. In addition to increasing pressure in order that force could be applied forcefully at target pieces via nozzles.

Blast Action:

This material goes into fast motion once accelerated through nozzles towards surface aimed at thus eliminating rusts among others. The impact forces remove undesirable objects like corrosion layers and painted surfaces within seconds.The strength and depth resulting from this process may depend on different adjustments that can be made by manipulating qualities associated with their course such as velocity or amount held back when forced out under great intensity respectively.

Cleaning Up and Exhaust:

Usually, the exhausted abrasives and particles are collected in separate bins or sucked into some vacuum system for easier disposal and to avoid messes. For instance, put on safety goggles, gloves and respiratory masks just to be sure that no one gets hurt by any shards flying out their way or end up swallowing dust.

The portability of the portable sand blaster allows for easy maneuverability and use in tight spaces or hard-to-reach areas. This tool is versatile enough for both large-scale projects with even small intricate jobs being easily accomplished. Nonetheless, it’s necessary follow the safety and operational guidelines as stipulated by the manufacturer so as not to expose oneself to accidents but also ensure it gives its best.

In conclusion, a portable sand blaster works by utilizing compressed air to propel abrasive particles at high speed, effectively cleaning and preparing surfaces. Its portability and versatility make it a valuable tool in various industries for surface preparation tasks.

The Impact of Stainless Steel Automatic Chocolate Decorating Machines

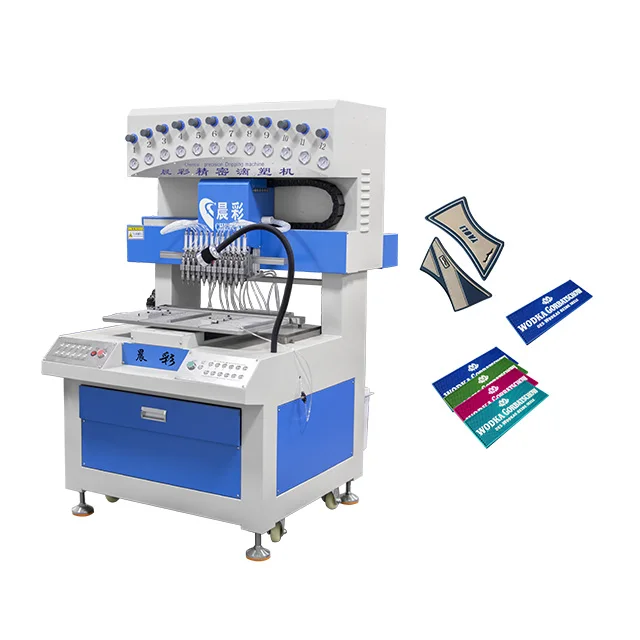

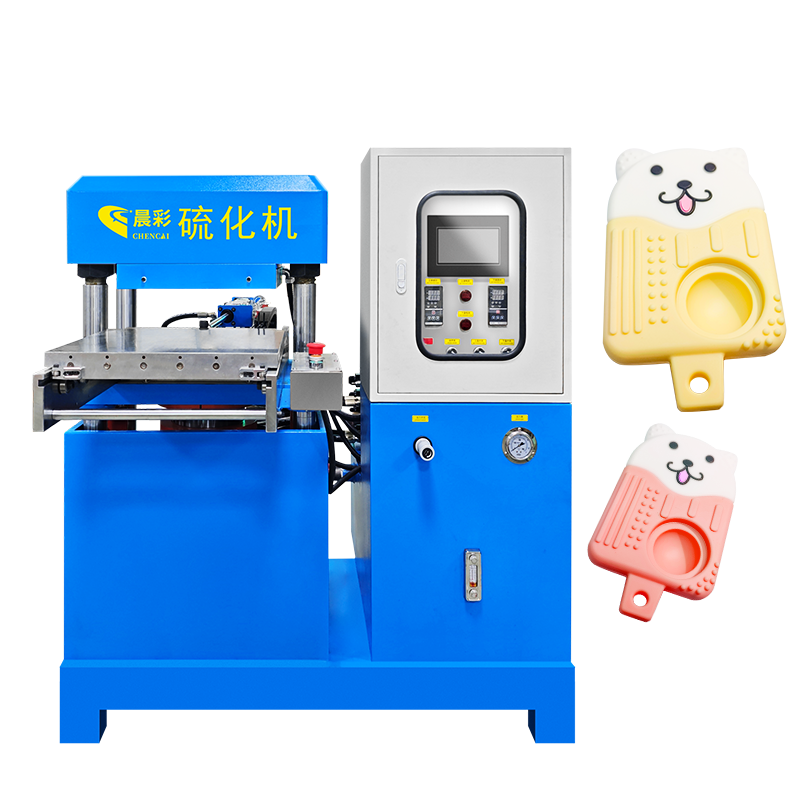

ALLA Breakthrough in Weather Resistant Silicone Labeling Machine

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

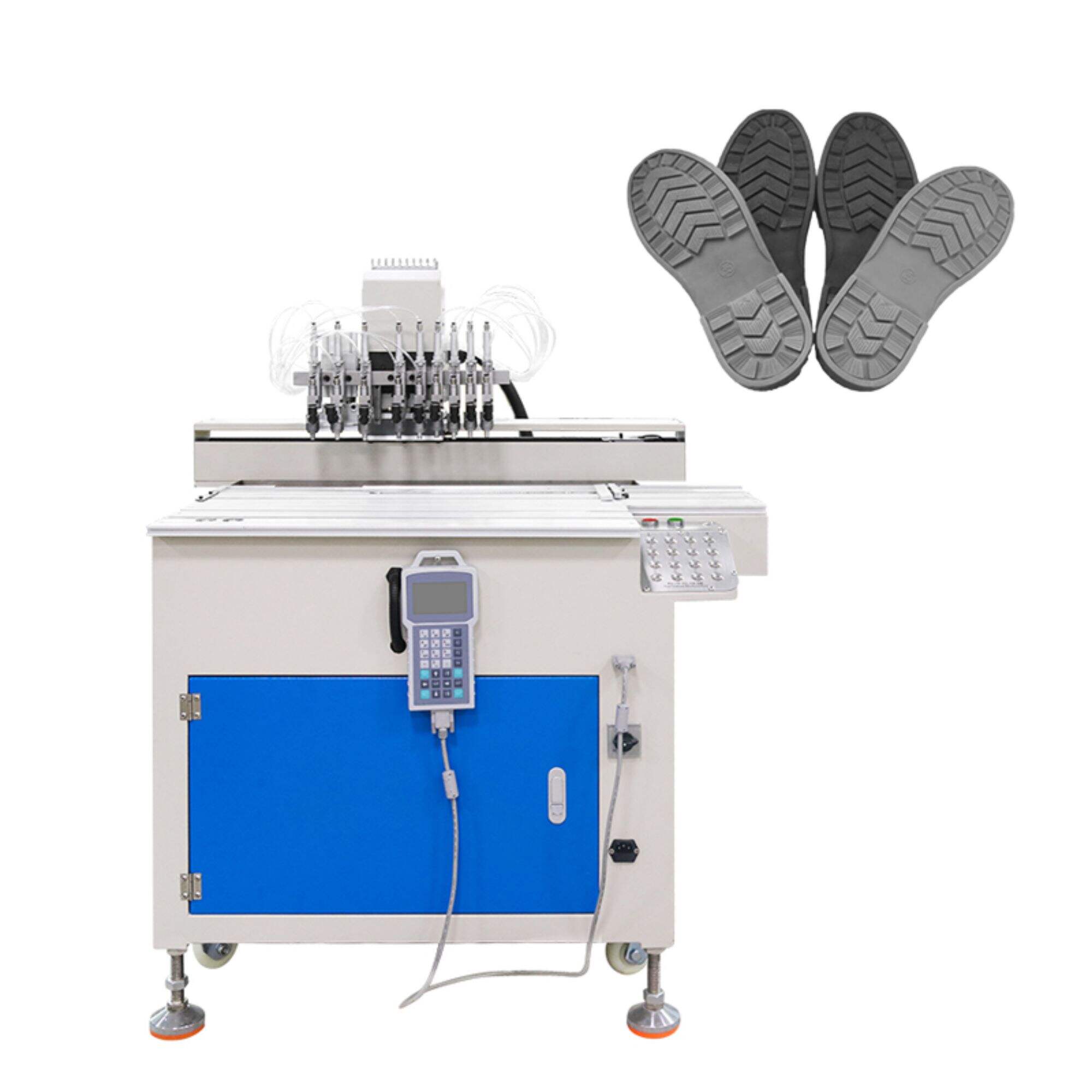

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY