Exploring the Functionality of Portable Sand Blasters

Introduction

Various types of industries employ portable sand blasters in carrying out surface preparation and restoration which is very effective. It is therefore paramount to understand how these multi-purpose machines work and the main components involved for their maximum utilization.

Principles of Operation

A portable sandblaster functions by pushing an abrasive material such as sand or grit, onto a surface at high speed so as to get rid of contaminations, rusting or old paintworks. These particles are forced with compressed air which results into a powerful blast that thoroughly cleans and prepares the surface for finishing or coating.

Components and Design

Typically, they consist of some sort of tank that pressurizes the abrasive substance, a blasting nozzle device, a compressor system and some controls. The abrasive substance is loaded inside this tank and it is then pressurized so it can be delivered effectively through the nozzle that does the blasting. Blasting process control demands proper air flow provided by air compressors to enable propulsion of abrasives.

Applications and Versatility

Portable sand blasters are used in many sectors such as automotive, construction, marine and manufacturing where surface preparation is critical. They have been developed to perform multiple tasks including: removing rust from metallic surfaces; cleaning concrete walls alongside brickwork among many others hence are highly useful tools in different professional areas.

Safety Considerations

When using portable sandblaster’s operators must take care since there could be particles moving at high speeds while they are working with them. Moreover, personal protective equipment like blast suits, gloves and respiratory protection should be put on to reduce any possibility of inhaling harmful substances thus making sure safety is maintained during blasting process.

Environmental Impact

To address this issue low-dust emission glass beads for instance made from recycled glasses or garnet that reduce dust emissions have been introduced into the market. In addition to that these waste granules cannot produce any hazardous while preparing surfaces thereby making it more sustainable because all these alternatives are consistent with their environmental obligation.

Conclusion

Portable sand blasters are vital in the surface treatment and renovation applications that take place in various industries which need the best surfaces. It is therefore important to be aware of how they work, safety considerations and their effects on the environment so as to make good use of them without violating stipulated policies by professions. Portable sand blasters will still remain a useful asset for maintaining or improving quality of different surfaces and materials even as technology keeps on advancing.

The Versatility of the Stainless Steel Automatic Chocolate Decorating Machine

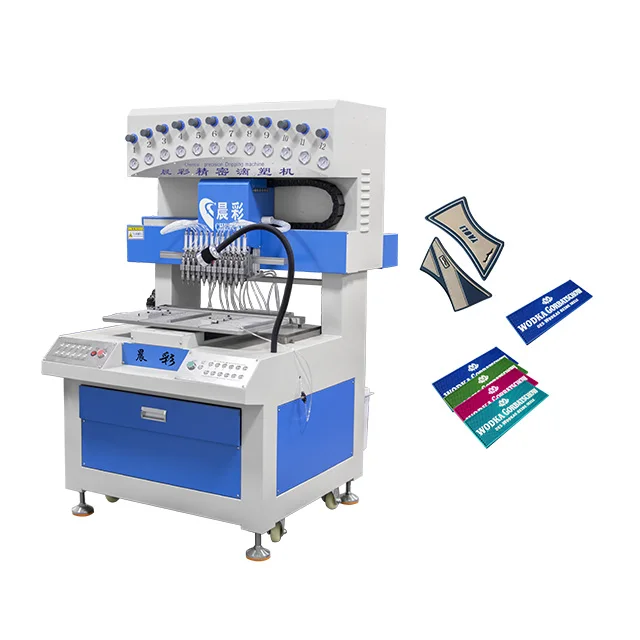

ALLThe Highly Versatile Power of Silicone Labeling Machines That Can Withstand Weather

NextRecommended Products

Hot News

-

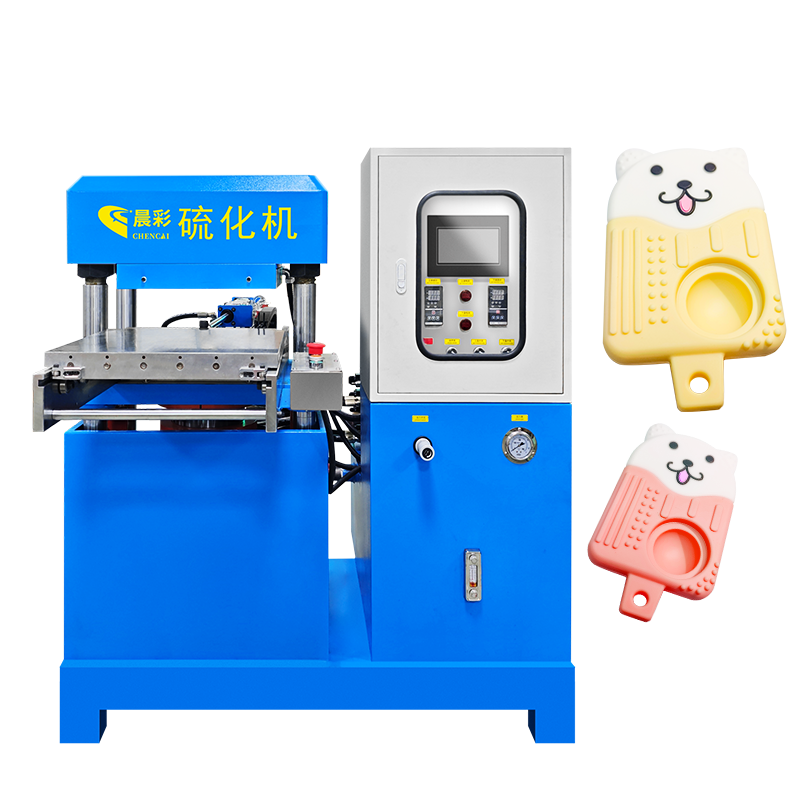

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY