Applications and Technological Innovations in Vulcanizing Machines for the Rubber Industry

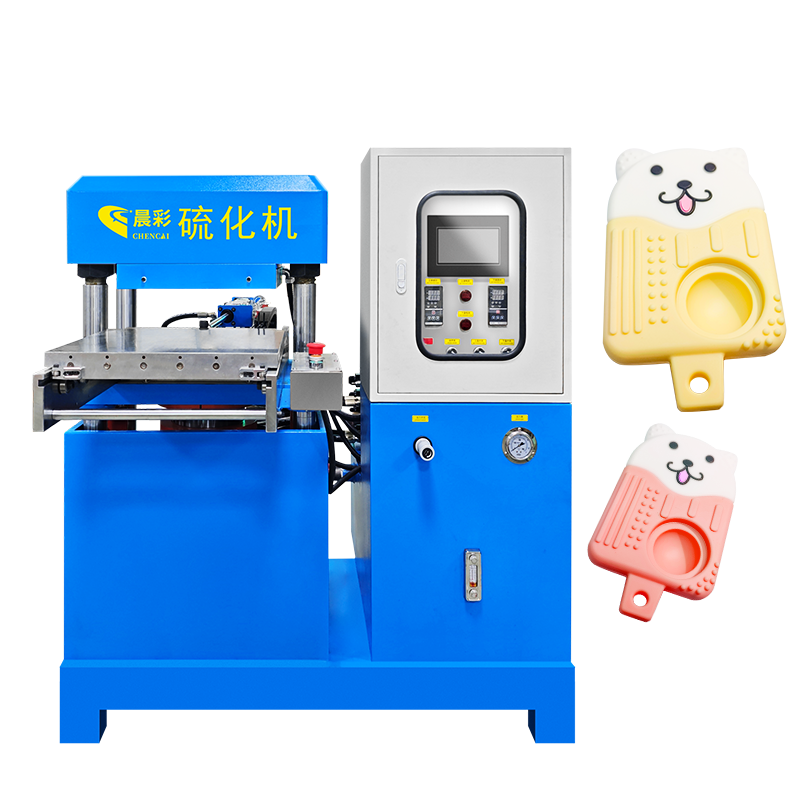

Vulcanizing machines are vital in the rubber industry because they help in the conversion of raw rubber into useful durable products. Vulcanizing machines devices aid the vulcanization processes, which are chemical changes that result in the cross-linking of rubber to improve its structural strength, elastic properties, and heat and abrasion resistance.

Vulcanizing machine uses

Tire making: Vulcanizing machines have become indispensable in the tire manufacturing industry, where they are necessary for curing tires for better performance. This ensures that the tires can be able to counter all forces that are usually exerted while driving such as high and low temperatures and mechanical forces.

Production of rubber goods: Apart from tires, vulcanizing machines are also used in the manufacture of various rubber products such as hoses, belts, seals and gaskets. These products are intended to be vulcanized under certain conditions for achieving the best quality.

Vulcanizing machine industrial usage: In industries, vulcanizing machines are applied in making products like rubber grommets and anti-vibration mounts. These elements are essential for the machinery, internal shields and also assist in eliminating noise during operation.

Technological innovations

Automation and control systems: As technology progresses, modern vulcanizing machines have incorporated more and more automation, or control systems, into production. These innovations promote controlled vulcanization in terms of temperature and pressure, thus optimizing the uniformity and quality of the process.

Energy efficiency: The current trend is that through the advancements in technology, the vulcanizing machines have become energy efficient. This is achieved by implementing energy-saving mechanisms and better insulation to the machines so that the total amount of energy use is decreased in the course of operations.

Smart monitoring: The recent vulcanizing machines offered to the market include smart monitoring features that explain the extent of curing in real-time. Such information improves the efficiency of the relevant personnel who staff that area by alerting them when something needs to be fixed in time.

Improved materials: The progress of technology in terms of materials and construction of machines has reduced the repair and maintenance periods considerably. Appropriate materials also enhance the service life of vulcanizing machines as they demonstrate optimum reliability even in extremely harsh operational environments.

Vulcanizing machines are the backbone of the rubber industry manufacturing tyres, industrial components and several other applications. The improvements in this area are linked to the various technological improvements including innovations through automation, energy efficiency, and smart monitoring systems.

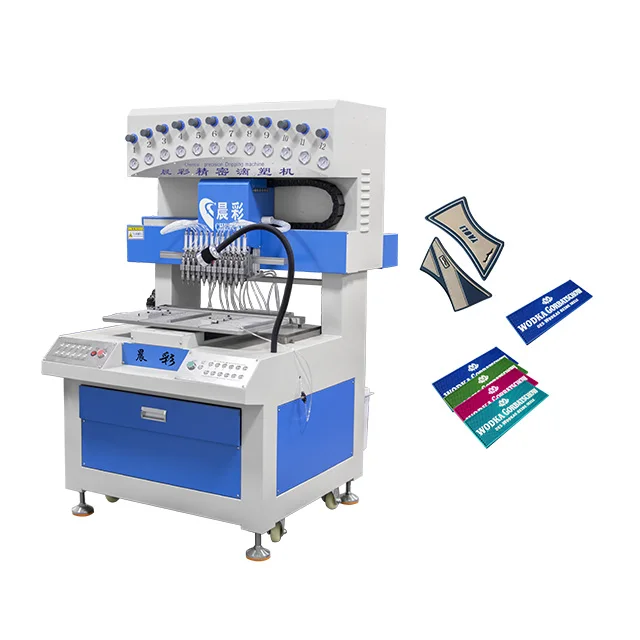

Applications of Silicone Label Machines in the Industry of Apparel and Accessories

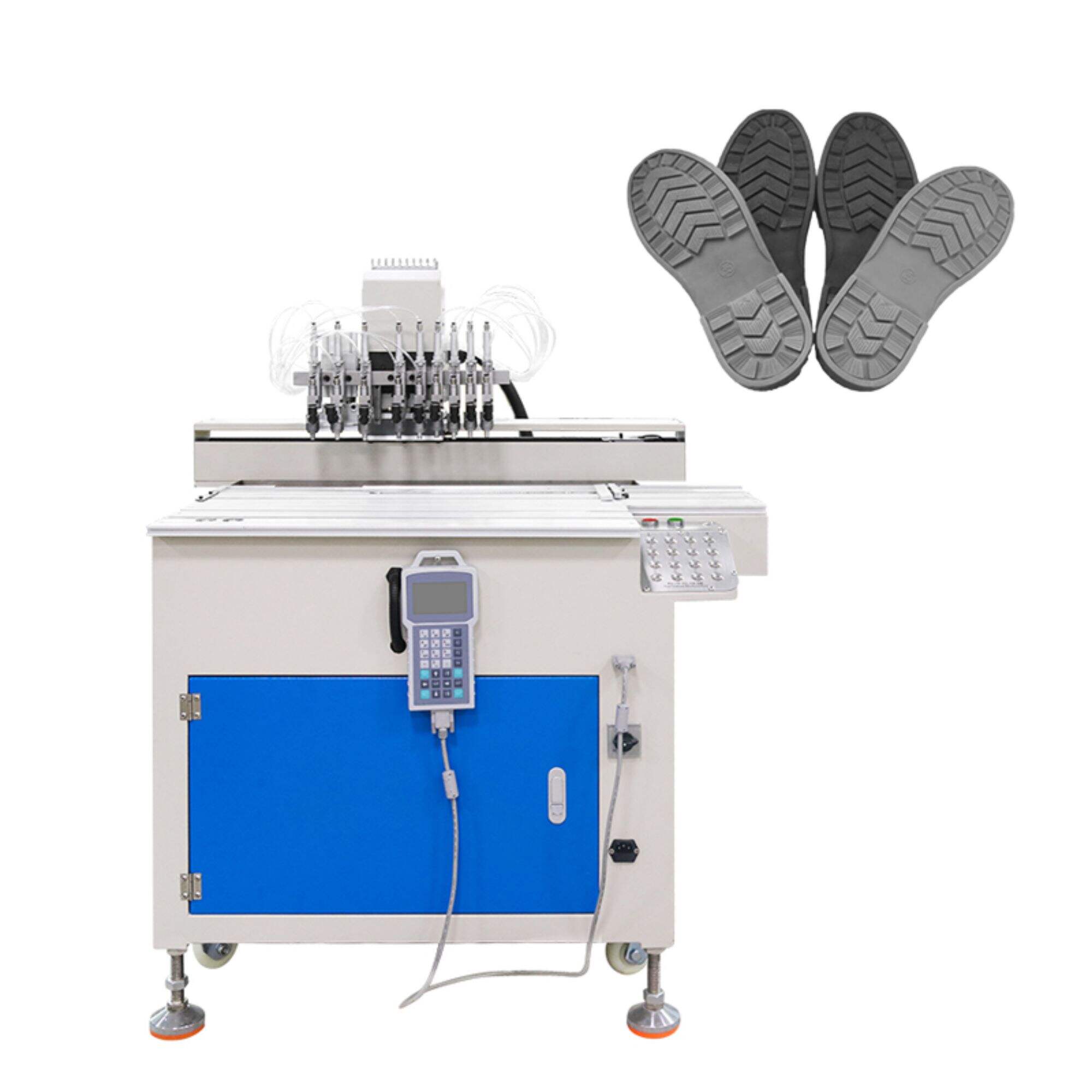

ALLThe Crucial Role of Silicone Dispensing Machines in Precision Manufacturing

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY