An Exhaustive Guide For Vertical Vulcanizing Machine Demystified

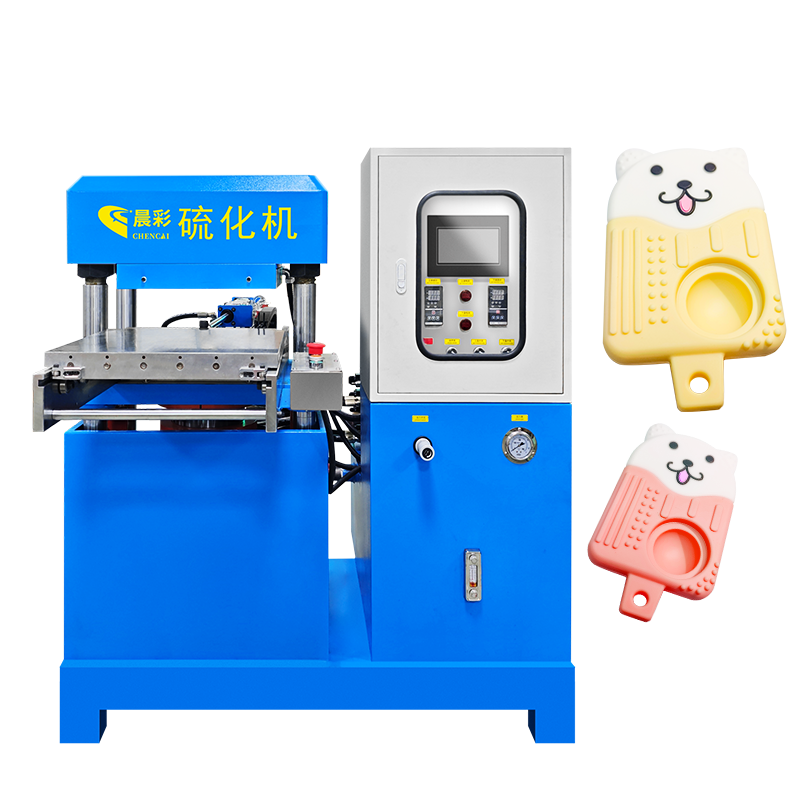

The Vertical vulcanizing machine is a vital facility in the rubber sector used during rubber product vulcanization.

Key components of vertical vulcanizing machines include heating elements, pressure system, molds and control system. The heating elements are responsible for increasing the temperature of the molds so as to facilitate vulcanization. The pressure system facilitates uniform curing by pressing against the rubber during the process of vulcanization; this in turn keeps air bubbles from forming. Molds are specifically made according to size and shape of rubber products that are being vulcanized. Control system oversees and maintains temperature and pressure levels throughout the entire period of curing.

Operating a Vertical Vulcanizing Machine

A vertical vulcanizing machine is operated by loading up into it a mold containing raw rubber material then closing it before starting the process of heating and hardening whereas heating elements warm up molds to needed temperatures, while a pressure system pressurizes on rubbers. The control unit also helps in keeping constant temperature and pressure through all stages of curing that typically last between 10 minutes to 30 minutes depending on thickness and nature of a product made out of rubber.

Applications for a Vertical Vulcanizing Machine

Vertical vulcanizers are commonly employed across tire making; belt manufacturing hose construction, production sealing products among others found in the output range pool.This makes vertical vulcanizer one must-have tool by any manufacturer who wants to be sure he produces good quality products at affordable price.

The vertical vulcanizing machine is an important equipment used in the rubber industry as it gives manufactures an efficient tool for processing rubber goods which can easily be relied upon during hard times.The most important part about this machine as highlighted above regarding its parts, operations and uses has established it as an essential instrument needed for making high standard products out of gum at pocket friendly terms. The vertical vulcanizing machine will always remain sacrosanct in rubber production as the world of synthetic materials advances.

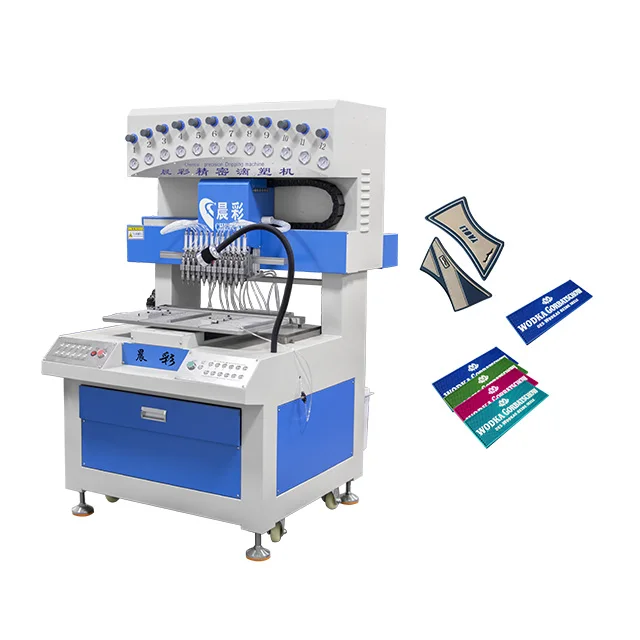

Efficient Silicone Label Machine For Branding Identification

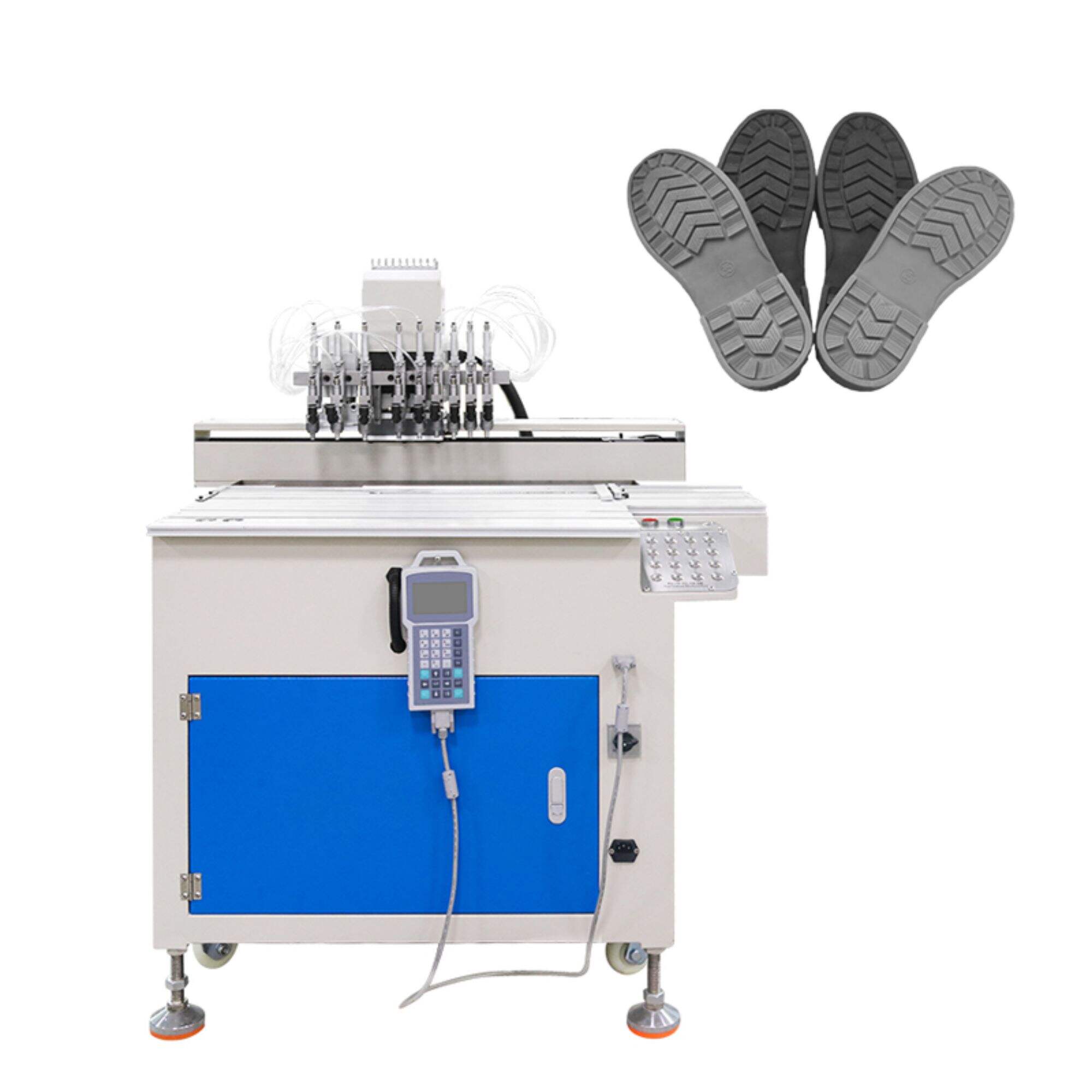

ALLEnhancing Precision With Automatic Silicone Dispensing Machine

NextRecommended Products

Hot News

-

Silicone Label Machine: An Efficient, Precise And Multifunctional Dispensing Machine

2023-12-27

-

Application And Development Trend Of Automatic Dispensing Machine In Electronics Industry

2023-12-27

-

The Principle, Characteristics And Advantages Of Automatic Dispensing Machine Are Introduced

2023-12-27

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BN

BN

BS

BS

MY

MY

KK

KK

UZ

UZ

KY

KY